Robotics Driving 25% Faster US Construction Timelines

The integration of robotics is fundamentally reshaping the US construction industry, offering unprecedented efficiencies that are demonstrably reducing project timelines by up to 25%, by automating repetitive, dangerous, and time-consuming tasks.

The landscape of the US construction industry is undergoing a profound transformation, driven by an unlikely, yet powerful, innovation: robotics. This technological shift is not merely incremental; it’s a paradigm change, promising to redefine efficiency, safety, and productivity on construction sites nationwide. The most striking outcome of this robotic integration is its proven ability to drastically shorten project timelines, with reports indicating reductions of up to 25%, fundamentally altering how America builds.

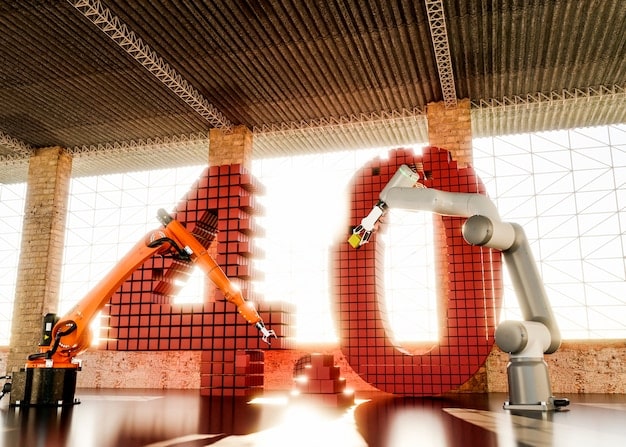

The Evolving Role of Robotics in Construction

The construction sector, traditionally characterized by manual labor and time-consuming processes, is now embracing automation at an accelerating pace. Robotics is no longer a futuristic concept but a tangible solution addressing pervasive industry challenges like labor shortages, safety concerns, and the insistent demand for faster project delivery. This shift marks a pivotal moment, ushering in an era where precision and speed become the norm rather than the exception.

Addressing Labor Shortages and Enhancing Safety

One of the most pressing issues facing the US construction industry is a chronic shortage of skilled labor. Robots can fill these gaps, performing tasks that are repetitive, physically demanding, or hazardous, thereby safeguarding human workers. This isn’t about replacing jobs wholesale, but rather augmenting human capabilities and reallocating workers to more complex, supervisory roles.

- Automated Bricklaying: Robots can lay bricks with superhuman speed and precision, reducing the time required for masonry work and minimizing human fatigue.

- Demolition Robots: Remote-controlled robots handle dangerous demolition tasks, protecting workers from falling debris and hazardous environments.

- Inspection Drones: Drones equipped with high-resolution cameras perform rapid site inspections, identifying potential issues without putting human inspectors at risk.

Boosting Productivity and Precision

Robotics introduces a level of precision and consistency that is difficult to achieve with manual labor alone. This accuracy not only speeds up construction but also reduces material waste and costly rework. From prefabrication to on-site assembly, robots are meticulously executing tasks, ensuring higher quality outputs. The sustained performance of robotic systems ensures that work proceeds without the slowdowns associated with human fatigue or breaks.

Early Adoption and Current Impact

While still in its relatively early stages of widespread adoption, the impact of robotics on various construction project phases is already becoming evident. Companies are investing in autonomous equipment, robotic arms for prefabrication, and AI-powered systems that optimize workflows. These initial deployments are yielding promising results, validating the investment in these advanced technologies. The integration is challenging traditional methodologies, pushing the industry towards a more optimized and data-driven future. The foundational shift in how tasks are approached is proving to be a catalyst for broader innovation across the sector.

The adoption of robotic solutions is driving a cultural change within construction, fostering an environment where innovation and efficiency are prioritized. This newfound capability allows projects to proceed at a pace previously unimaginable, directly correlating with significant reductions in overall project timelines. Project managers are discovering that the consistency and speed offered by robotic tools lead to more predictable schedules and fewer unforeseen delays.

Autonomous Equipment and Site Optimization

The vision of a fully autonomous construction site is steadily moving from concept to reality, primarily through the integration of self-driving machinery and intelligent site management systems. These advancements enhance efficiency and safety by operating with unparalleled precision and consistency across various tasks. This shift minimizes downtime and maximizes resource utilization, allowing for continuous, data-driven optimization.

Autonomous Excavators and Dozers

Large-scale earthmoving operations are prime candidates for automation. Autonomous excavators and bulldozers can operate around the clock, precisely following digital models to execute grading, trenching, and excavation tasks. These machines are equipped with advanced GPS, lidar, and sensor fusion technologies, enabling them to navigate complex terrains and perform tasks with minimal human intervention. Their ability to work tirelessly and accurately contributes significantly to maintaining tight schedules.

Robotic Surveying and Mapping

Traditional surveying is labor-intensive and time-consuming. Robotics, particularly through the use of drones and ground-based autonomous rovers, has revolutionized this process. These robotic systems can rapidly collect vast amounts of data, creating precise 3D maps and models of construction sites. This real-time data allows project managers to monitor progress, identify discrepancies, and make informed decisions, ensuring that projects stay on track and within budget.

- Volumetric Calculations: Drones can quickly calculate precise earthwork volumes, crucial for accurate material ordering and project planning.

- Progress Monitoring: Regular aerial scans provide updated site conditions, allowing comparison against planned progress.

- Hazard Identification: Automated surveys can detect unforeseen obstacles or ground instabilities, enabling proactive safety measures.

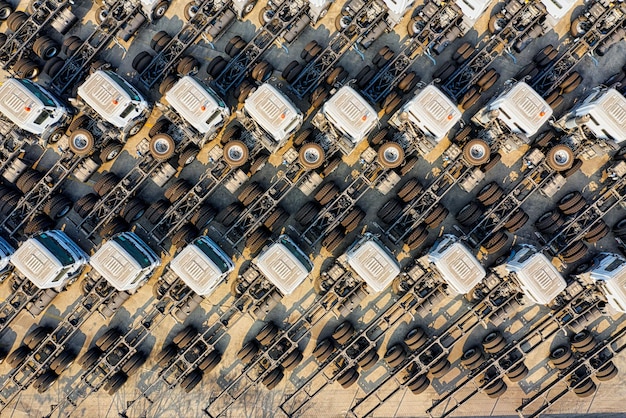

Optimizing Logistics and Material Flow

Beyond heavy machinery, robotics is also streamlining the logistical challenges inherent in construction. Automated guided vehicles (AGVs) and robotic forklifts are being deployed to manage material movement on site, ensuring that the right materials arrive at the right place at the right time. This reduces human error, prevents bottlenecks, and enhances overall site organization, contributing to a smoother construction flow. The precise coordination provided by these systems eliminates many of the common delays associated with manual logistic management.

The continuous operation of these autonomous systems means that tasks can be executed non-stop, without the need for breaks or shift changes, unlike human crews. This sustained pace is a critical factor in driving down project durations. The accuracy and repeatability of robotic operations also lead to fewer errors and less rework, which are significant sources of costly delays in traditional construction projects.

Prefabrication and Modular Construction with Robotics

The shift towards prefabrication and modular construction is heavily bolstered by robotic capabilities, offering a significant departure from traditional on-site building methods. By moving significant portions of the construction process into controlled factory environments, these techniques mitigate many of the variables and inefficiencies inherent in outdoor construction. Robotics enhances this approach by ensuring precision, speed, and consistency in the manufacturing of components.

Precision Manufacturing in Controlled Environments

Robotic arms and automated production lines are now commonplace in highly efficient fabrication facilities. These robots can cut, weld, assemble, and finish building components with extreme accuracy, far exceeding human capabilities. This precision is vital for modular construction, where perfectly fitting components are essential for rapid on-site assembly. The controlled environment eliminates weather delays, reduces material waste, and allows for continuous production cycles.

Benefits of Off-Site Construction

Moving construction tasks off-site results in numerous advantages that directly contribute to reducing project timelines. Factory settings allow for parallel workflows, meaning foundation work can begin on the construction site while modules are simultaneously being fabricated in the factory. This parallelization significantly compresses the overall project schedule.

- Reduced On-Site Labor: Less manual work directly on the construction site often translates to fewer safety incidents and logistical overheads.

- Improved Quality Control: Consistent factory conditions and robotic precision lead to higher quality, uniform components.

- Faster Assembly: Pre-built modules are simply delivered and assembled on-site, drastically cutting down the construction phase.

Robotic Assembly and Welding

Within these prefabrication facilities, robots are taking on demanding and repetitive tasks, such as complex welding and precise assembly of structural elements. Robotic welders provide consistent seam quality and speed, critical for structural integrity. Assembly robots handle heavy components, carefully placing them into position, ensuring that each module is built to exact specifications before it leaves the factory. This level of automation ensures a consistent output that is difficult to replicate manually.

The synergy between robotics and modular construction represents a powerful combination for efficiency. It allows for a manufacturing approach to building, where quality and speed are maximized through automation, directly resulting in the remarkable reduction in project timelines observed across the industry. The ability to produce building segments with industrial precision means that the on-site work is largely about connection and integration rather than fundamental construction, saving valuable time.

Advanced Robotics for On-Site Assembly

While prefabrication leverages robotics in a factory setting, the direct application of advanced robotic systems on active construction sites is equally transformative. These on-site robots handle complex and demanding tasks that previously required extensive manual labor, thereby enhancing safety, precision, and most importantly, accelerating the construction process. Their ability to adapt to dynamic environments marks a significant leap forward for the industry.

Robotic Bricklaying and Masonry

Traditional bricklaying is labor-intensive and requires significant skill and time. Robotic bricklayers, such as those developed by companies like Construction Robotics and Hadrian X, can lay bricks and blocks at speeds far exceeding human capacity, with impeccable accuracy. These machines use sophisticated vision systems and robotic arms to pick up, apply mortar, and precisely place bricks according to digital designs. This not only speeds up the exterior shell of buildings but also ensures structural integrity by minimizing human error.

Automated Rebar Tying and Welding

The creation of reinforced concrete structures involves placing and tying vast networks of rebar, a tedious and physically demanding task. Robotic systems are now capable of automating both rebar tying and on-site welding. These robots can rapidly secure rebar intersections, ensuring the structural reinforcement is correctly positioned and secured before concrete pouring. Automated welding robots can perform high-quality, consistent welds in challenging positions, further speeding up the structural phase of projects and enhancing overall safety.

- Faster Rebar Placement: Robots can tie rebar bundles significantly quicker than human laborers, accelerating the concrete pouring schedule.

- Consistent Weld Quality: Automated welding ensures uniform strength in steel connections, reducing the need for rework.

- Reduced Worker Exposure: Minimizing human presence in hazardous rebar cages and welding zones enhances site safety.

Facade Installation Robots

The installation of building facades, especially on high-rise structures, is a complex logistical challenge with safety implications. Robotic solutions are emerging that can assist or even fully automate the handling and placement of facade elements. These include specialized cranes with robotic grippers or autonomous aerial robots that can lift, position, and fasten panels. By reducing the reliance on manual lifting and precise positioning, these robots dramatically cut down facade installation times and improve worker safety at height.

The introduction of these on-site robotic solutions signifies a paradigm shift in how construction projects are executed. By automating critical, labor-intensive tasks, these systems directly contribute to the 25% reduction in project timelines by maintaining a consistent pace, ensuring high precision, and mitigating common human-related delays. Their growing presence makes construction sites safer, more efficient, and much faster.

Data-Driven Project Management with Robotic Integration

The advent of robotics in construction is not just about automating physical tasks; it profoundly impacts project management through enhanced data collection and sophisticated analytical capabilities. Integrated robotic systems generate vast amounts of real-time data, providing project managers with unparalleled insights into progress, performance, and potential issues. This shift to a data-driven approach allows for more agile decision-making and continuous optimization, directly contributing to compressed timelines.

Real-Time Progress Monitoring

Robots equipped with sensors, cameras, and GPS modules continuously record their activities and the state of the construction site. This data is fed into centralized project management platforms, providing live updates on work completed, material usage, and deviations from the planned schedule. Project managers can literally see the project unfolding in real-time, allowing for immediate corrective actions. This contrasts sharply with traditional methods, where progress updates might be delayed or based on manual estimations.

Predictive Analytics and AI

The huge datasets collected by robotic systems enable the application of predictive analytics and artificial intelligence. AI algorithms can analyze historical performance data from robotic operations to forecast future progress, identify potential bottlenecks before they occur, and even suggest optimized workflows. This proactive rather than reactive management style means that potential delays can be addressed early, often before they impact the overall project timeline.

- Resource Optimization: AI can predict optimal allocation of robotic and human resources based on real-time site conditions.

- Risk Mitigation: Early identification of potential structural or logistical issues through data analysis reduces costly delays.

- Schedule Adherence: Predictive models help adjust schedules dynamically to account for unforeseen variables.

Enhanced Quality Control and Error Reduction

The precision of robotic execution, combined with constant data feedback, significantly improves quality control. Any deviations from digital blueprints or specified tolerances are immediately flagged by the robotic systems themselves, preventing errors from propagating through subsequent construction phases. This immediate feedback loop minimizes rework, which is a major source of time and cost overruns in traditional construction projects. The consistency maintained by robotic operations ensures that quality is built in, rather than inspected in.

The integration of robotics transforms project management from a reactive, estimate-based discipline into a proactive, data-informed science. By leveraging the continuous flow of information from robotic systems, project managers can maintain a superior level of control over every aspect of a build, making adjustments with precision and foresight. This data-centric approach is a cornerstone of achieving and sustaining the significant reductions in project timelines seen today.

Challenges and the Path Forward for Robotics in US Construction

While the benefits of robotics in US construction are undeniable, particularly in reducing project timelines, the path to widespread adoption is not without its challenges. Overcoming these hurdles requires a concerted effort from all stakeholders: technology developers, construction firms, regulatory bodies, and the workforce itself. Addressing these issues will pave the way for a more efficient, safer, and ultimately more productive industry.

High Initial Investment and ROI Justification

Robotic construction equipment often comes with a substantial upfront cost, making it a significant investment for many firms, especially smaller ones. Justifying this investment requires a clear understanding of the long-term return on investment (ROI) through increased efficiency, reduced labor costs, and faster project delivery. Demonstrating quantifiable benefits and developing flexible acquisition models (e.g., leasing, Robots-as-a-Service) will be crucial.

Integration with Existing Workflows

Integrating advanced robotics into established, often traditional, construction workflows can be complex. It requires careful planning, new project management strategies, and interoperability between different systems (BIM, project management software, robotic control systems). Training existing personnel to supervise and maintain robotic equipment, rather than directly operate it, is also a critical consideration.

- Training and Upskilling: Developing new training programs to equip the current workforce with the skills needed to operate and maintain robotic systems.

- Data Standards: Establishing common data standards and formats to ensure seamless communication between various robotic systems and software platforms.

Regulatory and Safety Frameworks

The current regulatory landscape for construction was not designed with autonomous robots and AI in mind. Developing clear guidelines, safety protocols, and certification processes for robotic equipment operating on construction sites is essential to ensure compliance and worker safety. This involves collaboration between industry leaders and governmental bodies to create a forward-looking legal framework.

Acceptance and Workforce Adaptation

Perhaps one of the most subtle, yet significant, challenges is human acceptance. Concerns about job displacement often arise when new technologies are introduced. Fostering a narrative where robots augment human capabilities, handle dangerous tasks, and create new, higher-skilled jobs is crucial. Demonstrating the safety benefits and improved working conditions (e.g., fewer repetitive strain injuries) can help build trust and acceptance among the workforce.

The future of US construction with robotics is promising, offering solutions to chronic industry problems and the potential for unprecedented levels of efficiency. Overcoming these challenges requires strategic planning, continuous innovation, a commitment to workforce development, and proactive engagement with regulatory bodies. As these hurdles are addressed, robotics will continue to solidify its role as an indispensable tool in building the future, driving project timelines down significantly and reshaping the industry for decades to come.

| Key Benefit | Brief Description |

|---|---|

| ⏱️ Reduced Timelines | Robots automate tasks, accelerating project completion by up to 25%. |

| 👷 Enhanced Safety | Dangerous or repetitive tasks are handled by robots, protecting human workers. |

| ⚙️ Increased Precision | Robotic systems ensure consistent, high-quality work, minimizing errors and rework. |

| 📊 Data-Driven Management | Real-time data from robots optimizes decision-making and project flow. |

Frequently Asked Questions about Robotics in Construction

▼

Various robots are deployed, including automated bricklayers, demolition robots, inspection drones, autonomous excavators, and indoor robots for tasks like drywall installation and painting. Each type addresses specific needs, enhancing efficiency and safety across different project stages.

▼

Robotics reduce timelines by automating repetitive, labor-intensive tasks, working continuously without fatigue, performing dangerous jobs safely, and ensuring higher precision which minimizes errors and expensive rework. This translates to faster execution and reliable scheduling.

▼

While robots take over some tasks, the consensus is that they will augment human capabilities rather than entirely replace jobs. They create new roles in programming, maintenance, and supervision of robotic systems, allowing humans to focus on more complex and strategic aspects of construction.

▼

Beyond timeline reduction, key benefits include enhanced safety by removing humans from hazardous situations, improved construction quality due to robotic precision, reduced material waste, and better resource utilization through data-driven insights. It also helps address skilled labor shortages.

▼

Challenges include the high initial investment cost, the complexity of integrating robots with existing construction workflows, a lack of clear regulatory frameworks for autonomous systems, and the need for workforce upskilling to adapt to new technologies. Industry collaboration is crucial to overcome these.

Conclusion

The integration of robotics into the US construction industry is unequivocally ushering in a new era of efficiency and productivity. From automating repetitive tasks to enhancing safety and precision, robots are proving to be indispensable tools that not only address long-standing industry challenges but also fundamentally reshape project delivery. The evidence suggests that this technological revolution is significantly reducing project timelines, paving the way for more sustainable, cost-effective, and accelerated construction. As the industry continues to innovate and adapt, robotics will undoubtedly remain at the forefront, driving progress and building the infrastructure of tomorrow with unprecedented speed and accuracy.