US Robotics Industry Trends: Key Developments in Next 3 Months

The US robotics industry is poised for significant transformation in the next three months, with key developments focusing on advanced automation integration, AI-driven collaborative robots, and expanded applications across diverse sectors, driven by evolving technological capabilities and market demands.

As we navigate an era of rapid technological acceleration, understanding the immediate future of innovation becomes paramount. The US robotics industry trends: What are the key developments to watch in the next 3 months? will be shaped by a confluence of factors, from supply chain pressures to breakthroughs in artificial intelligence and automation. This sector, critical for productivity, national security, and economic competitiveness, continues to evolve at an impressive pace. Join us as we dissect the imminent shifts and critical advancements poised to redefine the landscape of robotics across the United States.

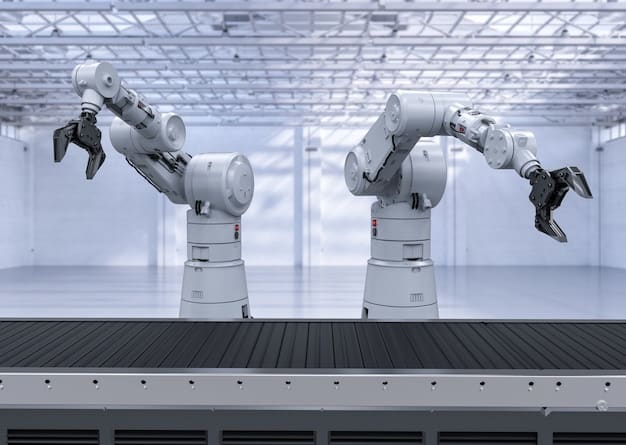

Accelerated Adoption of Advanced Automation

The imperative for increased manufacturing efficiency and reduced labor costs continues to drive the adoption of advanced automation solutions across industries in the United States. Over the next three months, we anticipate a significant acceleration in the deployment of sophisticated robotic systems, moving beyond traditional industrial arms to more versatile and intelligent platforms. This push is fueled by a desire to insulate operations from labor market volatility and to enhance precision and output quality.

Enterprises are increasingly recognizing that automation is not merely about replacing human labor but about augmenting human capabilities and creating new efficiencies. This paradigm shift encourages investment in robotics that can perform complex tasks, often in environments previously considered too challenging for machines.

Integration of AI and Machine Learning

The deep integration of artificial intelligence and machine learning algorithms into robotic systems is set to be a primary driver of development. This allows robots to learn from their environment, adapt to new tasks, and make semi-autonomous decisions, significantly enhancing their utility and flexibility.

- Enhanced Vision Systems: Robots are gaining sophisticated visual perception capabilities, enabling them to identify, sort, and manipulate objects with unprecedented accuracy, even in unstructured environments.

- Predictive Maintenance: AI algorithms embedded in robotic platforms can now predict potential equipment failures, scheduling maintenance proactively and minimizing downtime. This capability is invaluable in maintaining continuous operational flow.

- Adaptive Learning: New generations of robots are capable of “learning on the job,” observing human actions or processing data to refine their movements and task execution over time.

This integration facilitates the move towards more dynamic manufacturing processes, where robots can handle greater variation and complexity. The short-term focus will be on refining these AI capabilities to ensure robust and reliable performance across different industrial contexts.

Furthermore, the focus is expanding beyond just the factory floor. Logistics, material handling, and even service industries are looking to leverage these smarter automation tools to streamline operations and enhance customer experience. Expect to see early adopters in these sectors pushing the boundaries of what is possible with intelligent automation.

The Rise of Collaborative Robots (Cobots)

Collaborative robots, or cobots, represent a pivotal shift in how automation is perceived and implemented. Designed to work safely alongside human operators without the need for extensive safety caging, cobots are democratizing robotics, making automation accessible to a wider range of businesses, including small and medium-sized enterprises (SMEs). In the coming quarter, cobots are expected to see a significant surge in demand and deployment within US industries.

Their user-friendliness, often featuring intuitive programming interfaces and quick redeployment capabilities, makes them an attractive option for tasks that require both human dexterity and robotic precision. This flexibility allows businesses to adapt rapidly to changing production demands without major reconfigurations.

Enhanced Safety Features and Versatility

The evolution of cobots is marked by increasingly sophisticated safety features, including force sensing and speed limitations, which ensure that they can operate safely in shared workspaces. This emphasis on safety is crucial for broader acceptance and integration into human-centric work environments.

- Increased Payload and Reach: While early cobots often had limited capabilities, newer models are offering greater payload capacities and extended reach, enabling them to handle a broader array of tasks, from pick-and-place operations to quality inspection.

- Improved Dexterity: Advancements in end-of-arm tooling (EOAT) mean cobots are becoming more adept at fine manipulation, suitable for tasks requiring high precision like electronic assembly or intricate laboratory work.

- Plug-and-Play Integration: Manufacturers are focusing on making cobots easier to integrate into existing production lines, with standardized interfaces and modular components reducing setup time and technical barriers.

The versatility of cobots means they can be deployed in various sectors beyond traditional manufacturing, including healthcare, logistics, and even retail. The immediate future will see more specialized cobot applications emerge, tailored to specific industry needs, thereby unlocking new efficiencies and operational models.

As businesses seek to optimize their labor force and enhance productivity without fully automating every process, cobots offers a compelling middle ground. This balance between human effort and robotic assistance makes them particularly valuable in a dynamic economic climate where adaptability is key.

Expansion into New and Emerging Sectors

While manufacturing remains a core application, the US robotics industry is undergoing a significant diversification, with robots increasingly finding utility in sectors previously untouched by advanced automation. Over the next three months, we anticipate a notable expansion of robotic solutions into new and emerging markets, driven by technological advancements and evolving societal needs.

This diversification is not just about finding new customers but about addressing unique challenges across various industries, from improving patient care to enhancing agricultural output. The cross-pollination of robotic technologies from industrial settings to these novel applications is a testament to their adaptability and growing sophistication.

Healthcare and Logistics Applications

The healthcare sector is a prime area for growth, with robots aiding in surgeries, assisting patients, and automating laboratory tasks. In logistics, the explosion of e-commerce is driving demand for automated warehousing and last-mile delivery solutions.

Robots are becoming indispensable in hospitals for duties such as disinfecting rooms, delivering supplies, and even performing telepresence with infectious disease patients. This not only increases efficiency but also enhances safety for healthcare workers. Within logistics, autonomous mobile robots (AMRs) are streamlining warehouse operations, improving inventory management and order fulfillment speeds.

Agricultural and Service Robotics

Agriculture is ripe for robotic innovation, addressing labor shortages and improving resource efficiency. Service robotics, encompassing everything from autonomous cleaning machines to robots in hospitality, is also set for significant growth as businesses seek to automate repetitive tasks and enhance customer experience.

- Precision Agriculture: Robots are being developed to monitor crop health, pick produce, and apply pesticides with extreme precision, reducing waste and increasing yields.

- Autonomous Ground Vehicles (AGVs): Beyond warehouses, AGVs are finding use in various outdoor environments, from construction sites to large industrial complexes.

- Hospitality and Retail Automation: Robots are starting to serve customers, prepare food, and manage inventory in restaurants and stores, filling labor gaps and improving service consistency.

This expansion underscores the versatility of modern robotics and its capacity to revolutionize operations beyond traditional industrial settings. The next three months will likely see pilot programs scale up and new use cases emerge, solidifying robotics’ role in these diverse sectors.

The increasing complexity of global supply chains and the ever-present demand for faster, more efficient services are compelling industries to explore robotic solutions. This trend is set to accelerate, making robotics an indispensable part of various new economic landscapes.

Supply Chain Resilience and Onshoring Efforts

The volatility experienced in global supply chains over the past few years has profoundly impacted manufacturing and logistics across the United States. This has created a strong impetus for companies to enhance their supply chain resilience, with a significant push towards onshoring and nearshoring production. Robotics is playing a critical role in facilitating this strategic shift.

By automating processes previously outsourced, US companies can reduce their dependence on lengthy and unpredictable international supply routes. This not only mitigates risks but also allows for greater control over production quality and delivery times, fostering a more robust and adaptable domestic industrial base.

Automation as a Key to Domestic Production

The economic viability of bringing manufacturing back to the US often hinges on the ability to achieve cost-effectiveness comparable to offshore locations. Automation, particularly through advanced robotics, is the primary tool for achieving this. Robots can significantly reduce labor costs per unit and increase overall output.

This strategic investment in robotics enables domestic factories to remain competitive while operating within a higher wage economy. The emphasis is on “lights-out” manufacturing or highly automated processes where human intervention is minimized, allowing for continuous operation and maximizing efficiency.

- Reduced Lead Times: Onshoring production with robotics drastically cuts down on shipping times and customs delays, accelerating product delivery to market.

- Improved Quality Control: Automated inspection systems and robotic assembly lines offer unparalleled precision, leading to higher product quality and fewer defects.

- Enhanced Security of Supply: By producing locally, companies gain better oversight and control over their supply chain, protecting against geopolitical disruptions and natural disasters.

In the coming quarter, we anticipate that more businesses will announce plans to leverage robotics for onshoring initiatives, particularly in sectors deemed strategically important, such as electronics, pharmaceuticals, and critical components. Government incentives and a renewed focus on national industrial capabilities are further accelerating this trend.

This strategic reorientation has cascading effects throughout the economy, creating demand for skilled robotics technicians, engineers, and researchers. The pursuit of supply chain resilience through robotics is thus contributing to a broader revitalization of the US manufacturing sector.

Focus on Human-Robot Interaction (HRI) and Training

As robots become more ubiquitous in various work environments, the quality of human-robot interaction (HRI) is gaining critical importance. The next three months will place a stronger emphasis on developing more intuitive and user-friendly interfaces for robots, alongside comprehensive training programs for human workers. This ensures seamless collaboration and maximizes the potential benefits of automation.

Effective HRI is not just about making robots easier to operate; it’s about fostering trust, improving safety, and enabling humans and robots to work together synergistically. This necessitates designing robots that can understand human intent, communicate effectively, and adapt to human work styles, rather than the other way around.

Intuitive Programming and Safer Interactions

A key development is the move towards “programming by demonstration” and natural language interfaces, reducing the need for highly specialized coding skills. This democratizes robot operation, allowing more workers to interact directly with and even reprogram robotic systems.

Furthermore, advancements in sensor technology and AI are making human-robot interactions significantly safer. Robots are increasingly aware of their surroundings and human presence, able to adjust their speed or stop completely to prevent collisions.

- Voice and Gesture Control: Future robots will respond to verbal commands and hand gestures, making interaction more natural and efficient, particularly in dynamic work settings.

- Augmented Reality for Training: AR tools are being used to overlay digital instructions onto physical robots, providing immersive and effective training for operators and maintenance staff.

- Ergonomic Design: Consideration for human comfort and safety is being integrated into robotic design, ensuring that physical interactions are safe and intuitive.

The development of robust training programs is equally vital. As robotics technology advances, so too must the skills of the human workforce. Companies are investing in upskilling their employees, teaching them how to operate, maintain, and troubleshoot robotic systems, preparing them for the jobs of tomorrow.

This dual focus on HRI and training is essential for overcoming potential resistance to automation and ensuring that the integration of robots leads to a productive and harmonious work environment. The synergy between human ingenuity and robotic efficiency is the ultimate goal.

Regulatory Frameworks and Ethical Considerations

The rapid advancement and widespread deployment of robotics in the US are bringing critical discussions around regulatory frameworks and ethical considerations to the forefront. Over the next three months, stakeholders — including government bodies, industry leaders, and academic institutions — are expected to intensify their dialogues on establishing guidelines that balance innovation with accountability and societal well-being.

These discussions aim to address concerns related to safety, data privacy, liability, and the socio-economic impacts of automation, particularly on employment. Proactive engagement in these areas is essential to foster public trust and ensure responsible development of robotic technologies.

Developing Safety Standards and Data Protections

As robots move from controlled industrial environments into public spaces and homes, the need for robust safety standards becomes paramount. This includes establishing clear protocols for autonomous operation, collision avoidance, and emergency responses.

Concurrently, the increasing connectivity of robots means they gather and process vast amounts of data. Crafting effective regulations for data privacy and cybersecurity is crucial to protect sensitive information and prevent malicious exploitation. This involves defining who owns the data, how it is collected and stored, and who has access to it.

- ANSI/RIA Standards: American National Standards Institute (ANSI) and Robotic Industries Association (RIA) are continually updating safety standards (e.g., ANSI/RIA R15.06) to reflect new technologies and application areas for industrial robots and cobots.

- Privacy by Design: Developers are encouraged to incorporate privacy features into robotic systems from the initial design phase, rather than as an afterthought.

- Liability Frameworks: Discussions are ongoing to define liability in cases of robot malfunction or accident, particularly for autonomous systems, which is critical for legal clarity and insurance.

The ethical dimensions extend to addressing the societal impact of automation, including job displacement and the need for workforce reskilling initiatives. Policymakers and industry leaders are grappling with how to ensure that the benefits of robotics are broadly shared and that transitions for affected workers are managed responsibly.

The next few months will likely see the publication of white papers, policy recommendations, and perhaps initial legislative proposals aimed at providing a clearer regulatory landscape for the robotics industry, ensuring healthy growth without compromising public interest.

Venture Capital Investment and Ecosystem Growth

The US robotics industry continues to attract substantial venture capital (VC) investment, signaling strong confidence in its future growth potential. Over the next three months, we anticipate continued robust funding rounds for innovative robotics startups and established companies, further fueling research, development, and commercialization. This investment is crucial for propelling the industry forward, enabling breakthroughs, and accelerating market penetration.

Beyond direct financial injections, this period will also see an intensified focus on ecosystem growth, with new partnerships, collaborations, and incubation programs designed to nurture promising technologies and facilitate market entry for nascent ventures. The synergistic interplay between capital and innovation is key to maintaining the US’s leading position in robotics.

Strategic Partnerships and M&A Activities

A characteristic of a maturing industry is the rise in strategic partnerships and mergers & acquisitions (M&A) activities. In the coming quarter, we expect to see more collaboration between robotics firms and companies in sectors like manufacturing, construction, and healthcare, aiming to develop tailored solutions.

M&A activities will likely focus on acquiring specialized technologies, expanding market share, or consolidating fragmented segments of the industry, particularly in areas like autonomous mobile robots, AI-driven vision systems, and advanced manipulation.

- Startup Accelerators: More accelerators and incubators specialized in robotics are emerging, providing not only funding but also mentorship, technical resources, and networking opportunities.

- Academic-Industry Collaborations: Universities with strong robotics programs are increasingly partnering with industry players on research projects, translating cutting-edge academic work into marketable products.

- Government Grants & Initiatives: Federal and state governments are allocating funds through grants and initiatives to support robotics research and development, particularly for applications in defense, infrastructure, and critical supply chains.

This vibrant ecosystem, fueled by venture capital, is essential for translating cutting-edge research into practical applications and bringing new solutions to market efficiently. The focus in the short term will be on identifying and backing scalable technologies that can address immediate market needs and deliver significant returns.

The competitive landscape demands continuous innovation, and sustained investment is the lifeblood of this progress. The next three months will offer a clear indication of which technological trends are gaining the most traction among investors and strategic partners, shaping the immediate direction of the US robotics industry.

| Key Development | Brief Description |

|---|---|

| ⚙️ Accelerated Automation | Increased deployment of sophisticated robotic systems, driven by efficiency and cost reduction demands. |

| 🤝 Rise of Cobots | Surge in collaborative robots working safely alongside humans, boosting accessibility for SMEs. |

| 🏥 New Sector Expansion | Significant growth in healthcare, logistics, agriculture, and service robotics applications. |

| 🔗 Supply Chain Resilience | Robotics crucial for onshoring efforts to mitigate supply chain volatility and enhance domestic production. |

Frequently Asked Questions About US Robotics Trends

▼

A “cobot” or collaborative robot is designed to work safely alongside humans in a shared workspace without requiring extensive safety barriers. They are important because they are typically user-friendly, flexible, and can be easily reprogrammed for different tasks, making advanced automation accessible and cost-effective for a wider range of businesses, including small and medium-sized enterprises (SMEs).

▼

Artificial Intelligence (AI) is profoundly impacting the US robotics industry by enabling robots to learn, adapt, and make intelligent decisions. This integration leads to enhanced vision systems for precise manipulation, predictive maintenance capabilities to minimize downtime, and adaptive learning that allows robots to refine tasks based on real-time data, significantly increasing their versatility and efficiency in complex environments.

▼

Beyond traditional manufacturing, emerging sectors in the US are rapidly adopting robotics to streamline operations. Key areas include healthcare (for surgery, patient assistance, and lab automation), logistics (for automated warehousing and last-mile delivery), agriculture (for precision farming and harvesting), and service industries (for autonomous cleaning, hospitality tasks, and retail operations), addressing labor shortages and improving efficiency.

▼

Robotics significantly contributes to supply chain resilience by enabling onshoring and nearshoring of production. By automating manufacturing processes domestically, companies can reduce reliance on volatile global supply chains, cut down lead times, improve quality control, and gain greater control over their production. This helps mitigate risks from geopolitical events or logistical disruptions, making domestic production economically viable and more secure.

▼

The main ethical considerations in US robotics development revolve around safety, data privacy, liability, and socio-economic impacts. Discussions focus on establishing robust safety standards for autonomous systems, ensuring data protection and cybersecurity, defining legal liability in case of malfunctions, and addressing potential job displacement through workforce reskilling initiatives. These considerations are vital to ensure responsible innovation and public trust.

Conclusion

The US robotics industry is on the cusp of transformative change within the next three months, driven by technological advancements, evolving market demands, and strategic imperatives. From the accelerating adoption of intelligent automation and the proliferation of collaborative robots to the expansion into new sectors and the crucial role in bolstering supply chain resilience, the scope of robotics is broadening significantly. Coupled with a heightened focus on human-robot interaction, robust regulatory frameworks, and sustained venture capital investment, the industry is poised for substantial growth and innovation. These developments collectively underscore robotics as a foundational pillar of future economic competitiveness and societal advancement across the United States. The dynamism within this sector promises a landscape of enhanced productivity and evolving job roles, shaping a more automated and efficient future.