US Robotics Standards 2025: Impact on Automation Adoption

The updated US robotics standards, set to significantly influence the industry by 2025, are poised to enhance safety, interoperability, and ethical considerations, thereby accelerating automation adoption across manufacturing, logistics, and healthcare sectors.

As we approach 2025, the landscape of industrial and service robotics in the United States is on the cusp of significant transformation. The impending updates to US robotics standards are not merely technical adjustments; they represent a pivotal moment that could redefine how quickly, safely, and effectively automation technologies are integrated across various sectors. Understanding how will the updated US robotics standards impact automation adoption in 2025? is crucial for businesses, policymakers, and innovators alike, as these changes promise to address long-standing challenges and unlock new opportunities for growth and efficiency.

Understanding the Landscape of Robotics Standards

The evolution of robotics standards is a continuous process, driven by technological advancements, safety concerns, and the increasing integration of robots into daily life. Historically, standards have provided a common language for designers, manufacturers, and end-users, ensuring that systems are safe, reliable, and interoperable. In the US, a complex web of organizations, including the American National Standards Institute (ANSI) and the National Institute of Standards and Technology (NIST), works to develop and refine these guidelines. Their efforts are essential in laying the groundwork for how new robotic technologies can be safely deployed and effectively utilized. These standards often cover everything from mechanical design to software protocols, aiming to create a cohesive operational environment.

The current updates are particularly noteworthy because they reflect a maturing industry. Early standards focused primarily on industrial robots in controlled environments, emphasizing physical safety barriers and predictable movements. However, with the rise of collaborative robots (cobots), autonomous mobile robots (AMRs), and AI-driven systems, the scope of safety and performance requirements has broadened considerably. These newer robots operate in much more dynamic and often shared spaces with humans, necessitating a more nuanced approach to risk assessment and operational protocols.

Key Areas of Update: Safety and Interoperability

Two primary pillars of the updated standards are enhanced safety protocols and improved interoperability. For safety, the focus has shifted from mere physical separation to intelligent human-robot interaction. This includes clearer guidelines for speed and force limiting, collision avoidance, and intuitive user interfaces that allow humans to understand and predict robot behavior. The aim is to create environments where robots can work alongside humans without posing undue risk, fostering trust and acceptance.

Interoperability, meanwhile, addresses the challenge of integrating diverse robotic systems and components from various manufacturers. In the past, proprietary systems often created silos, hindering flexibility and scalability. The updated standards aim to promote open architectures and common communication protocols, allowing different robots, sensors, and software platforms to work seamlessly together. This is crucial for enabling more complex automation solutions and reducing the total cost of ownership for businesses.

- Enhanced Safety Protocols: Focus on human-robot collaboration, predictive behavior, and advanced collision detection.

- Standardized Communication: Promotion of open-source and common communication protocols to improve system integration.

- Modular Design Principles: Encouragement of modular components for easier maintenance, upgrades, and system scalability.

- Risk Assessment Frameworks: Updated guidelines for evaluating and mitigating risks in dynamic and unstructured environments.

These updates are not just about compliance; they are about unlocking the full potential of robotics by making them safer, more versatile, and easier to deploy. By addressing these foundational aspects, the standards aim to remove significant barriers that have historically slowed the pace of automation adoption.

Impact on Manufacturing and Industrial Automation

The manufacturing sector has long been a pioneer in robotics adoption, but the updated US robotics standards are set to usher in a new era of efficiency and flexibility. Traditional industrial robots, encased in protective cages, are slowly being complemented by collaborative robots (cobots) that work directly alongside humans. The new standards provide much-needed clarity on how these cobots can be safely integrated into factory lines, allowing for closer human-robot teaming and more agile production processes. This shift will enable manufacturers to automate more tasks that require human dexterity or decision-making at certain stages, leading to improved productivity and reduced labor costs for repetitive tasks. It’s a move away from rigid, isolated automation to a more fluid, integrated approach.

Furthermore, the emphasis on interoperability will benefit manufacturers by simplifying the integration of different robotic systems and peripheral equipment. Imagine a scenario where a vision system from one vendor can seamlessly communicate with a robot arm from another, all controlled by a central software platform that integrates with existing enterprise resource planning (ERP) systems. This level of integration means faster setup times, easier maintenance, and the ability to adapt production lines quickly to changing market demands. Small and medium-sized enterprises (SMEs), which often lack the resources for complex custom integrations, stand to gain significantly from these standardized approaches, making advanced automation more accessible to them.

Predictive Maintenance and Quality Control

The updated standards also touch upon aspects that indirectly support advanced applications like predictive maintenance and enhanced quality control. By standardizing data formats and communication protocols, robots can more effectively share operational data with analytical platforms. This allows for real-time monitoring of robot health, predicting potential failures before they occur, and scheduling maintenance proactively, thereby minimizing downtime. In quality control, robots equipped with advanced sensors and vision systems can perform meticulous inspections, identify defects with higher accuracy, and report findings through standardized interfaces, leading to consistent product quality. This level of data integration and analysis is a game-changer for maintaining competitive edge.

Additionally, the standards encourage the development of robot systems that are easier to program and reconfigure. This flexibility is vital in modern manufacturing, where product cycles are shorter and customization is increasingly common. Manufacturers can reprogram robots for new tasks with minimal downtime, allowing them to respond rapidly to shifts in production requirements or new product introductions. The overall effect on the manufacturing sector will be a more resilient, efficient, and adaptable production ecosystem, capable of meeting the demands of a dynamic global market.

The updated standards will likely accelerate the adoption of robotics in manufacturing by making these technologies safer, more adaptable, and economically viable for a wider range of businesses. By addressing both the technical and operational aspects, they create a stronger foundation for smart factories of the future.

Transforming Logistics and Supply Chain Operations

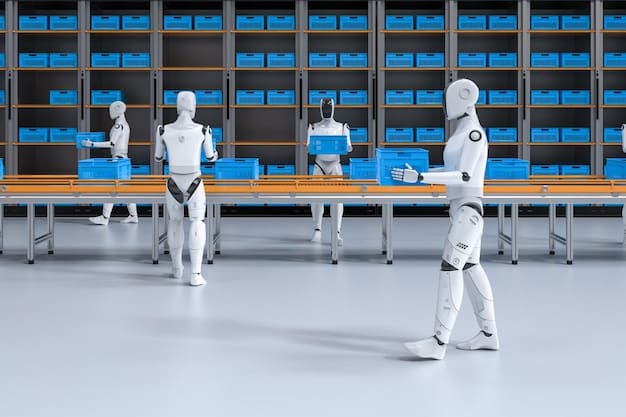

The logistics and supply chain sectors are prime candidates for increased automation, and the updated US robotics standards will act as a significant catalyst. Warehouses, distribution centers, and fulfillment operations already heavily rely on automation, but the next wave will see widespread adoption of autonomous mobile robots (AMRs) and advanced sortation systems. The new standards provide clearer guidelines for the safe operation of AMRs in shared spaces with human workers, addressing concerns around collision avoidance, route planning, and interaction protocols. This clarity will boost confidence among logistics providers, allowing them to deploy AMRs more extensively for tasks like inventory management, order picking, and internal transport, significantly reducing manual labor and improving operational speed.

Moreover, the emphasis on interoperability will streamline the integration of various robotic solutions within the complex logistics ecosystem. A typical warehouse might use AMRs for transport, robotic arms for picking, and automated storage and retrieval systems (AS/RS). Ensuring these diverse systems can communicate and coordinate effectively is paramount for efficient operations. The updated standards will facilitate this integration, allowing companies to avoid vendor lock-in and build more flexible, scalable automation solutions. This means faster implementation cycles and improved return on investment (ROI) for automation projects.

Optimizing Last-Mile Delivery and Inventory Management

The impact extends beyond the warehouse to last-mile delivery. While still in nascent stages, autonomous delivery robots and drones are being piloted. The updated standards will likely provide initial frameworks for their safe and regulated operation, particularly in urban and suburban environments. This could pave the way for more widespread testing and eventual commercial deployment, addressing challenges like labor shortages and increasing consumer expectations for rapid delivery. For inventory management, the ability of robots to conduct frequent, accurate cycle counts and report data in standardized formats will lead to significantly improved inventory accuracy and reduced stockouts, which are critical for customer satisfaction.

- Enhanced AMR Safety: Clearer guidelines for autonomous navigation, human interaction, and emergency protocols in dynamic warehouse environments.

- Integrated Logistics Platforms: Standards to enable seamless data exchange between AMR fleets, robotic arms, and warehouse management systems (WMS).

- Reduced Labor Dependencies: Automation of repetitive and physically demanding tasks, freeing human workers for more value-added roles.

- Scalable Automation Solutions: Easier expansion and modification of robotic systems to adapt to fluctuating demand and operational changes.

By providing a robust regulatory framework, the updated standards will not only foster innovation in logistics automation but also provide the necessary assurances for businesses to invest in these transformative technologies. This will lead to more resilient, faster, and cost-effective supply chains, which are vital in today’s global economy.

Robotics in Healthcare and Service Industries

Beyond traditional industrial sectors, the updated US robotics standards are poised to significantly influence the adoption of automation in healthcare and various service industries. In healthcare, robots are increasingly used for tasks ranging from surgical assistance and rehabilitation to dispensing medications and disinfecting facilities. The new standards will likely place a strong emphasis on the safety and reliability of robots operating in close proximity to patients and sensitive equipment, accelerating their acceptance. This includes guidelines for sterile environments, human-robot interaction in clinical settings, and data security for patient information handled by robotic systems. Such clarity is vital for hospitals and clinics to confidently invest in these advanced tools, knowing they meet rigorous safety and ethical benchmarks.

Service industries, from hospitality to retail, are also exploring robotics for tasks like cleaning, customer service, and food preparation. Here, the standards will play a crucial role in regulating robots that interact directly with the public. Imagine a hotel lobby with an autonomous concierge robot; the standards would dictate its navigation capabilities, verbal interaction protocols, and emergency procedures. By providing a clear framework for responsible deployment, these updates will help overcome public hesitation and accelerate the integration of service robots into everyday consumer experiences. This ensures that the benefits of automation can be realized without compromising public safety or privacy.

Ethical AI and Data Privacy Considerations

A burgeoning area of concern for all sectors, particularly healthcare and public services, is the ethical dimension of AI-powered robotics. The updated standards are expected to address this by including guidelines on data privacy, algorithmic transparency, and accountability for autonomous decision-making. In healthcare, for instance, robots handling patient data must comply with strict privacy regulations like HIPAA. The standards will provide a roadmap for ensuring that robotic systems are designed and operated in an ethically responsible manner, building trust among users and the wider public.

- Patient Interaction Safety: Specific protocols for robots assisting in surgeries, therapy, and patient care to ensure minimal risk.

- Sterilization and Hygiene: Standards for robotic systems operating in clinical and food service environments to prevent contamination.

- Data Security for Sensitive Information: Guidelines for protecting patient and customer data processed or stored by robotic devices.

- Ethical AI Frameworks: Development of rules for algorithmic bias, transparency, and accountability in autonomous robot decisions.

The implications for healthcare include more efficient operations, reduced risk of human error in repetitive tasks, and improved patient outcomes through precise robotic assistance. In service industries, robots can enhance customer experiences, handle mundane tasks, and improve overall operational efficiency. The updated standards will be instrumental in ensuring this expansion happens responsibly, fostering innovation while prioritizing human well-being and trust.

Challenges and Opportunities for 2025

While the updated US robotics standards promise significant benefits, their implementation also presents both challenges and unparalleled opportunities for 2025 and beyond. One primary challenge lies in the sheer complexity of developing standards that encompass a rapidly evolving technological landscape. Robotics technology is advancing at an exponential rate, making it difficult for regulatory bodies to keep pace. Ensuring that standards are forward-looking enough to accommodate future innovations, without being overly prescriptive, is a delicate balancing act. There is also the challenge of industry adoption; even well-crafted standards require widespread awareness, training, and a willingness from businesses to invest in compliance.

Another hurdle is the global nature of the robotics industry. While US standards are crucial, international harmonization is equally important to facilitate global trade and prevent market fragmentation. Differences in national regulations can create barriers for manufacturers operating across borders. Policymakers must work collaboratively with international bodies to ensure a degree of alignment, reducing the burden on companies and accelerating global automation adoption. Furthermore, smaller businesses might struggle with the resources required to understand and implement complex new standards, potentially widening the gap between large and small enterprises in terms of automation capabilities.

Economic and Workforce Opportunities

Despite these challenges, the opportunities presented by the updated standards are immense. By creating a clearer, safer, and more interoperable environment for robotics, the standards will significantly de-risk automation investments for businesses. This predictability will encourage greater capital expenditure in robotics, leading to expanded markets for robot manufacturers, integrators, and software developers. The economic stimulus from this increased investment could be substantial, fostering job creation in design, engineering, maintenance, and data analysis related to robotic systems. It’s not just about replacing jobs, but transforming the nature of work and creating new, higher-skilled roles.

From a workforce perspective, the standards offer an opportunity to proactively address concerns about job displacement. By emphasizing human-robot collaboration and designing systems that augment human capabilities rather than simply replacing them, the standards can guide the development of robots that enhance productivity while prioritizing human roles. This requires a focus on reskilling and upskilling programs to prepare the workforce for an automated future, turning potential disruption into an opportunity for human-machine synergy. The updated regulations will drive innovation but also ensure responsible technological deployment.

Ultimately, the successful implementation of these standards in 2025 will hinge on effective communication, continuous adaptation, and a collaborative effort between government, industry, and academia. Navigating these complexities will unlock a future where automation is not just prevalent but also safe, ethical, and universally beneficial.

Future-Proofing Automation: Beyond 2025

Looking beyond 2025, the updated US robotics standards lay a critical foundation for future-proofing automation adoption. The rapid pace of technological change necessitates that regulatory frameworks are not static but living documents, capable of evolving with new discoveries and applications. The current updates are just one step in a continuous journey towards a more intelligent, autonomous, and integrated world. A key aspect of future-proofing involves building mechanisms for iterative review and revision into the standards development process. This agility will ensure that standards remain relevant as robotics incorporates more advanced AI, quantum computing, or exotic materials.

Another vital element is the proactive consideration of emerging ethical and societal implications. As robots become more sophisticated and integrated into sensitive areas like personal care or autonomous decision-making, questions around liability, accountability, and the very definition of “human” work will become more pressing. Future standards will need to tackle these complex philosophical and legal challenges head-on, ideally through foresight rather than reaction. This will require multi-disciplinary dialogues involving ethicists, legal experts, social scientists, and technologists, ensuring that the development trajectory of robotics aligns with societal values and promotes human flourishing.

Education and Public Acceptance

Long-term adoption is not just about technical compliance; it’s also about public understanding and acceptance. Future-proofing automation requires a concerted effort in education and outreach to demystify robotics and address public concerns. The standards can play a role here by providing clear, understandable guidelines that build public trust in autonomous systems. By transparently outlining safety protocols, ethical considerations, and the benefits of automation, the standards can help shape a positive public perception. This involves educating the next generation of engineers, policymakers, and end-users about responsible robotics development.

- Adaptive Regulatory Mechanisms: Implementing systems for regular review and update of standards to keep pace with technological advancements.

- Proactive Ethical Frameworks: Addressing emerging ethical questions in AI and robotics, such as bias, accountability, and societal impact.

- International Collaboration: Working towards global harmonization of standards to facilitate cross-border innovation and market access.

- Public Education Initiatives: Fostering widespread understanding and acceptance of robotic technologies through clear communication and educational programs.

The journey of automation adoption extends far beyond 2025. The updated US robotics standards are an important milestone, but the true test will be how effectively they can evolve and adapt to meet the challenges and opportunities of an increasingly automated future. By prioritizing flexibility, ethical considerations, and public engagement, these standards can ensure that robotics remains a force for progress and positive societal transformation.

| Key Point | Brief Description |

|---|---|

| ⚙️ Enhanced Safety | New guidelines focusing on human-robot collaboration and risk mitigation in dynamic environments. |

| 🌐 Greater Interoperability | Promotion of open architectures and common communication protocols for seamless system integration. |

| 🏭 Boosted Adoption | Increased confidence and reduced complexity will accelerate automation in manufacturing, logistics, and services. |

| 💡 Ethical AI Integration | Addressing data privacy, algorithmic transparency, and accountability for autonomous systems. |

Frequently Asked Questions About Robotics Standards

The main goals are to enhance safety for human-robot interaction, improve interoperability between different robotic systems, and address ethical considerations such as data privacy and algorithmic transparency. These aims seek to build trust and facilitate broader, more responsible adoption of robotics across sectors in the US.

Small and medium-sized businesses will likely benefit from clearer guidelines and improved interoperability, making advanced automation more accessible and less costly to implement. Standardized solutions can reduce the need for expensive custom integrations, lowering barriers to entry for automation for smaller enterprises.

While some roles may be redefined, the standards aim to foster human-robot collaboration, creating new job opportunities in robot design, maintenance, and data analysis. The focus is on augmenting human capabilities and ensuring a responsible transition, requiring upskilling of the workforce.

Ethical AI is a critical component, addressing concerns around data privacy, algorithmic bias, and accountability for autonomous decision-making. The standards aim to ensure that robotic systems operate in a manner that is fair, transparent, and respectful of human values, particularly in sensitive applications.

International cooperation is vital for harmonizing standards globally, which reduces market fragmentation and barriers to trade. Aligned regulations allow for easier development and deployment of robotic technologies across different countries, fostering innovation and broader market reach for US companies.

Conclusion

The updated US robotics standards for 2025 mark a significant inflection point for automation adoption across the nation. By prioritizing enhanced safety, fostering greater interoperability, and proactively addressing ethical considerations, these standards are poised to accelerate the integration of robotics from manufacturing floors to healthcare facilities and logistics warehouses. They offer a much-needed framework that builds confidence, reduces implementation complexities, and unlocks new economic opportunities. While challenges in keeping pace with rapid technological evolution and ensuring widespread adoption persist, the strategic foresight embedded in these standards will ultimately drive the responsible and beneficial proliferation of automation, shaping a future where human innovation and robotic capability work in seamless synergy.