The Future of Robotics in US Manufacturing: A 5-Year Forecast

The next five years promise a significant transformation in US manufacturing, as advancements in robotics technology facilitate increased automation, enhance productivity, and redefine the workforce, with a strong focus on collaborative robots, AI integration, and reshoring initiatives.

As we stand on the cusp of an industrial renaissance, The Future of Robotics in US Manufacturing: A 5-Year Forecast unveils a landscape where innovation, automation, and strategic investment converge to redefine American production. This exploration delves into the pivotal role robotics will play in shaping the sector’s trajectory.

the evolving landscape of us manufacturing

The US manufacturing sector has long been a linchpin of the nation’s economy, renowned for its innovation and productivity. However, recent decades have seen shifts, with some production moving offshore. Now, a confluence of factors – including supply chain vulnerabilities, rising labor costs elsewhere, and a renewed emphasis on domestic production – is paving the way for a transformative period, largely driven by robotics.

This re-evaluation of manufacturing strategies is not merely about bringing jobs back, but about creating more resilient, efficient, and technologically advanced production ecosystems. The integration of robotics is central to this vision, offering unparalleled precision, speed, and safety in operations that were once exclusively human domains. The next five years are critical for solidifying this transition.

drivers of robotic adoption

Several key factors are accelerating the adoption of robotics in US manufacturing. One prominent driver is the persistent challenge of labor shortages in skilled trades. As older generations retire, filling roles that require specialized expertise becomes increasingly difficult. Robots can bridge this gap, taking on repetitive, hazardous, or highly precise tasks, freeing human workers for more complex, supervisory, or creative roles.

Another significant factor is the global push for increased competitiveness. Manufacturers worldwide are leveraging automation to reduce costs, improve quality, and accelerate time-to-market. For the US to maintain its competitive edge, embracing these advanced technologies is not just an option but a necessity. The pursuit of higher operational efficiency and error reduction also plays a crucial role.

- Labor Scarcity: Addressing the shortage of skilled workers in various manufacturing segments.

- Global Competitiveness: Enabling US manufacturers to compete effectively on price, quality, and speed.

- Operational Efficiency: Streamlining processes, reducing waste, and optimizing production cycles.

- Safety Enhancements: Removing humans from dangerous or monotonous tasks, leading to fewer workplace injuries.

The imperative for agility and adaptability in supply chains, highlighted by recent global disruptions, further underscores the need for automated solutions. Robotics provides the flexibility to rapidly reconfigure production lines, adapt to changing market demands, and produce goods closer to home, thereby reducing reliance on distant and often fragile supply chains.

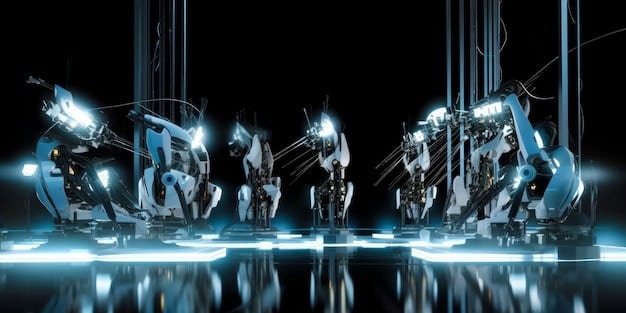

collaborative robots and human-robot interaction

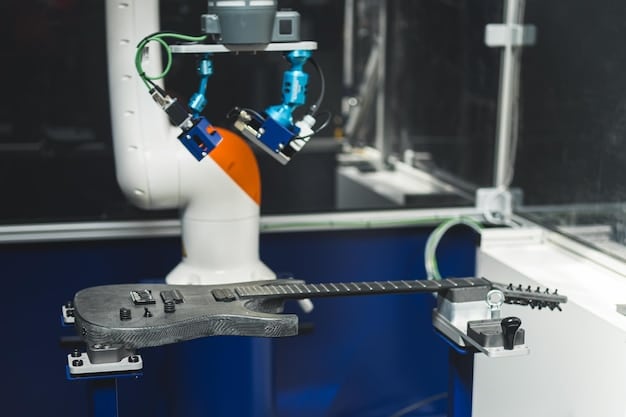

Perhaps one of the most significant shifts anticipated in the next five years regarding industrial robotics is the widespread adoption of collaborative robots, or “cobots.” Unlike traditional industrial robots that operate behind safety cages, cobots are designed to work safely alongside human colleagues, often sharing the same workspace without extensive safety barriers. This paradigm shift marks a move from full automation to “augmentation,” where technology enhances human capabilities rather than replacing them outright.

The ability of cobots to perform repetitive or ergonomically challenging tasks, while humans focus on cognitive, supervisory, or delicate operations, unlocks new levels of efficiency and flexibility on the factory floor. They are particularly valuable for small and medium-sized enterprises (SMEs) that may lack the capital or space for large, fixed automation systems. Their relatively lower cost, ease of programming, and adaptability make them an attractive entry point into automation.

cobots: a growing presence

The market for cobots is projected to grow substantially, driven by their versatility and the increasing need for agile manufacturing processes. These robots are not confined to a single task; they can be quickly reprogrammed for different applications, from assembly and material handling to quality inspection and packaging. This adaptability makes them ideal for custom orders and flexible production lines, allowing manufacturers to respond rapidly to market changes.

The integration of cobots also fosters a different type of workforce, one that is highly skilled in overseeing and interacting with robotic systems. Training programs focused on human-robot collaboration will become increasingly important, ensuring that the workforce is equipped to maximize the potential of these emerging technologies. This doesn’t simply involve operating machinery but understanding how best to integrate robotic assistance into existing workflows.

- Enhanced Safety Features: Built-in sensors and algorithms that allow for safe human interaction.

- Ease of Programming: Often featuring intuitive, drag-and-drop interfaces accessible to non-specialists.

- Flexibility and Adaptability: Quick re-tasking for various applications and production runs.

- Reduced Footprint: Requiring less space than traditional industrial robots, ideal for crowded facilities.

Human-robot interaction will evolve beyond simple task sharing. Voice commands, gesture control, and even augmented reality interfaces are being explored to make collaboration even more seamless and intuitive. The goal is to create a symbiotic relationship where humans and robots each bring their unique strengths to the manufacturing process, resulting in higher quality products and more efficient operations.

the role of artificial intelligence and machine learning

The true power of future robotics in manufacturing will be significantly amplified by the integration of artificial intelligence (AI) and machine learning (ML). While robots traditionally execute pre-programmed tasks, AI and ML provide them with the ability to learn, adapt, and make intelligent decisions in real-time. This cognitive leap transforms robots from mere tools into powerful problem-solvers capable of continuous improvement.

AI-powered robots can analyze vast amounts of data from sensors, production history, and external sources to optimize their operations. For instance, they can predict equipment failures, adjust parameters to improve product quality, or optimize complex assembly sequences. This predictive maintenance and adaptive manufacturing capability is a game-changer for overall equipment effectiveness and efficiency.

smarter robots, smarter factories

Machine learning algorithms enable robots to learn from experience, refine their movements, and improve their performance over time. A robot performing a welding task, for example, can learn from successful welds and adjust its parameters to ensure consistency and quality, even as conditions change slightly. This self-optimization reduces the need for constant human supervision and fine-tuning, leading to higher productivity and fewer defects.

Beyond individual tasks, AI will orchestrate entire fleets of robots and other automated systems within a smart factory environment. AI-driven platforms will manage production schedules, reallocate resources based on demand fluctuations, and ensure a seamless flow of materials and products. This level of interconnectedness and intelligent automation will define the factories of tomorrow, fostering unprecedented levels of efficiency and responsiveness.

- Predictive Maintenance: Identifying potential equipment issues before they lead to downtime.

- Dynamic Optimization: Real-time adjustments to production parameters for improved quality and efficiency.

- Cognitive Automation: Robots learning from data and adapting to unforeseen circumstances.

- Integrated Systems: AI orchestrating complex workflows across multiple robotic and automated units.

Another area where AI will prove invaluable is in quality control. Advanced vision systems, powered by deep learning, can identify minuscule defects that might be missed by the human eye or traditional inspection methods. This ensures a higher quality output, reduces waste, and contributes to a stronger brand reputation. The ability to continually refine and improve product standards through AI-driven inspection is a significant competitive advantage for US manufacturers.

impact on the manufacturing workforce

A recurring concern surrounding the rise of robotics is its potential impact on the human workforce. While some roles may be automated, the more accurate forecast suggests a transformation, rather than outright displacement, of labor. The future manufacturing workforce will likely be a hybrid one, where humans and robots collaborate, each bringing unique strengths to the production process.

The jobs of tomorrow will increasingly focus on tasks that require creativity, critical thinking, problem-solving, and interpersonal skills – areas where humans still excel. This includes roles in robot programming, maintenance, data analysis, system integration, and supervisory positions. The emphasis will shift from manual labor to intellectual labor, demanding a new set of skills from employees.

upskilling and reskilling initiatives

To prepare the workforce for this automated future, extensive upskilling and reskilling initiatives will be crucial. Educational institutions, industry associations, and manufacturing companies themselves will need to partner to develop curricula that equip workers with the necessary technical skills, such as robotics programming, data science, and advanced manufacturing processes. Lifelong learning will become the norm.

Furthermore, human-robot collaboration requires skills beyond the purely technical. Understanding how to interact effectively with robots, troubleshoot issues, and leverage their capabilities will be vital. Companies will also need to focus on change management, addressing employee anxieties about automation through transparent communication and clear pathways for career progression in the new manufacturing landscape.

- New Job Creation: Roles in robot maintenance, programming, data analysis, and system integration.

- Skill Shift: Emphasis on cognitive, problem-solving, and creative abilities over manual tasks.

- Training Imperative: Need for comprehensive upskilling and reskilling programs.

- Human-Robot Teaming: Developing effective collaborative workflows and interaction protocols.

The manufacturing workforce will become more specialized and technologically proficient. Instead of feeling threatened, employees will likely find themselves empowered by robots that handle the mundane, dangerous, or repetitive aspects of their jobs, allowing them to focus on more engaging and value-added activities. This evolution promises not just higher productivity but potentially more satisfying and safer work environments for human employees.

supply chain resilience and reshoring

The COVID-19 pandemic laid bare vulnerabilities in global supply chains, prompting many US manufacturers to reconsider their reliance on overseas production. The concept of “reshoring” – bringing manufacturing operations back to the United States – has gained significant traction, and robotics will be a key enabler of this trend in the next five years.

While overseas production often benefits from lower labor costs, advanced robotics significantly narrows this cost differential. Automated factories require fewer human workers, meaning the labor cost advantage of offshore locations becomes less significant. This allows US manufacturers to produce goods competitively on home soil, reducing lead times, transportation costs, and risks associated with geopolitical instability or distant disruptions.

building domestic capacity

Robotics facilitates the creation of highly efficient, flexible, and responsive domestic manufacturing capabilities. With automated lines, production can be scaled up or down rapidly to meet fluctuating demand, and customization becomes more feasible. This intrinsic flexibility contributes to greater supply chain resilience, ensuring that critical goods can be produced reliably within national borders, irrespective of global events.

Moreover, reshoring supported by robotics also offers environmental benefits by reducing the carbon footprint associated with long-distance shipping. It also ensures higher quality control, as manufacturers have direct oversight of the entire production process. The strategic imperative of national security, particularly for critical industries like defense and medical supplies, further strengthens the case for robot-driven domestic production.

- Cost Parity: Robotics narrowing the labor cost gap with offshore manufacturing.

- Reduced Lead Times: Faster production and delivery by producing closer to end markets.

- Enhanced Control: Direct oversight of quality and production processes.

- Environmental Benefits: Lower carbon emissions from reduced global transport.

The next five years will see increased government incentives and private sector investment aimed at accelerating reshoring initiatives. Robotics will be at the forefront of this effort, transforming US factories into highly automated, interconnected “smart factories” capable of supporting robust domestic supply chains and reinforcing economic sovereignty.

challenges and considerations for widespread adoption

While the trajectory for robotics in US manufacturing appears promising, several significant challenges and considerations must be addressed for widespread and successful adoption over the next five years. Navigating these obstacles will be crucial for realizing the full potential of this technological wave.

One primary hurdle is the initial capital investment required for robotic systems. Although prices are decreasing and ROI periods are shortening, the upfront cost can still be prohibitive for smaller manufacturers. Furthermore, integrating new robotic systems into existing legacy infrastructure can be complex and costly, requiring significant planning and potentially temporary production disruptions.

overcoming implementation hurdles

The technical expertise required for deploying, programming, and maintaining advanced robotic systems is another critical factor. While cobots are easier to use, complex industrial robots still demand specialized skills. A shortage of qualified engineers and technicians capable of managing these systems could slow down the adoption rate significantly. This underscores the importance of education and workforce development mentioned earlier.

Cybersecurity is an increasingly vital concern. As factories become more automated and interconnected through the Industrial Internet of Things (IIoT), they become more vulnerable to cyberattacks. Protecting proprietary data, operational integrity, and intellectual property from sophisticated threats will require robust cybersecurity measures and continuous vigilance. A breach could cripple production and jeopardize sensitive information.

- High Initial Costs: Significant capital expenditure for hardware and integration.

- Integration Complexity: Challenges in seamlessly incorporating new tech into old systems.

- Skill Gap: Shortage of personnel trained in robotics and automation.

- Cybersecurity Risks: Protecting interconnected systems from malicious attacks.

Ethical considerations also emerge as robots become more autonomous. Questions around data privacy, algorithmic bias, and the societal impact of automation on employment require thoughtful long-term strategies. While not direct implementation hurdles, these broader considerations will influence public perception and policy, ultimately shaping the pace and nature of robotic integration into the manufacturing ecosystem. Addressing these challenges proactively will ensure a smoother and more responsible transition to a robot-driven future.

| Key Point | Brief Description |

|---|---|

| 🚀 Automation Surge | US manufacturing will significantly increase robotic adoption to boost efficiency and competitiveness. |

| 🤝 Cobot Collaboration | Collaborative robots (cobots) will become commonplace, working seamlessly with human operators. |

| 🧠 AI Integration | AI and machine learning will power smarter, adaptive robots for optimized production and quality control. |

| 📦 Reshoring Drive | Robotics will enable more US-based manufacturing, enhancing supply chain resilience and reducing reliance on overseas production. |

frequently asked questions

▼

The primary driver is a combination of factors, including persistent labor shortages in skilled manufacturing roles and the global imperative for increased competitiveness. Robotics helps bridge skill gaps, improves efficiency, and allows US manufacturers to produce goods more cost-effectively and with higher quality, maintaining their standing in the global market.

▼

Cobots will revolutionize factory floors by enabling humans and robots to work side-by-side without extensive safety barriers. This safe interaction allows cobots to handle repetitive or strenuous tasks, freeing human workers for more complex, cognitive, or creative responsibilities, thus increasing overall productivity and flexibility in production lines, especially appealing for SMEs.

▼

AI and machine learning will be crucial for making robots more intelligent and adaptive. They will enable robots to learn from data, predict equipment failures, optimize production parameters in real-time, and perform advanced quality control. This integration leads to smarter factories, predictive maintenance, and continuous improvement, moving beyond static programming.

▼

No, robots are unlikely to entirely replace human jobs. Instead, they will transform the nature of work. Repetitive and dangerous tasks will be automated, creating new roles in robot programming, maintenance, data analysis, and system integration. The future workforce will be a hybrid one, where humans supervise and collaborate with robotic systems, focusing on higher-value activities.

▼

Robotics will significantly contribute to supply chain resilience and reshoring by making domestic manufacturing more cost-effective and competitive. By reducing reliance on human labor for certain tasks, robots narrow the cost gap with overseas production, facilitating the return of manufacturing to the US. This creates more robust and flexible domestic supply chains, reducing geopolitical and logistical risks.

conclusion

The next five years represent a pivotal period for US manufacturing, with robotics poised to drive an unprecedented transformation. From enhancing productivity and bolstering competitiveness to fostering supply chain resilience and redefining the workforce, intelligent automation is not merely a trend but a foundational shift. While challenges such as initial investment and the need for new skills remain, the strategic imperative for adoption is clear. The collaborative synergy between humans and increasingly sophisticated robotic systems, powered by AI and machine learning, will forge a more agile, efficient, and domestically robust manufacturing sector. This evolution promises not only economic growth but also a renewed global leadership position for American industry in the years to come.