US Robotics Market Analysis 2025: Fastest Growing Sectors

The US Robotics Market Analysis: Which Sectors are Seeing the Fastest Growth in 2025? reveals a dynamic landscape where healthcare, logistics, and agricultural robotics are poised for significant expansion, driven by innovation, labor shortages, and increasing demand for automation across various industries in the United States.

As we approach 2025, the robotics market in the United States continues its remarkable ascent, driven by burgeoning technological advancements and a compelling need for efficiency across numerous industries. Unpacking the US Robotics Market Analysis: Which Sectors are Seeing the Fastest Growth in 2025? reveals not just trends, but seismic shifts promising to redefine productivity, safety, and the very fabric of American enterprise. This exploration delves into the sectors demonstrating the most rapid growth, offering insights into where ingenuity meets demand, signaling a future increasingly shaped by autonomous systems and intelligent machines.

The Burgeoning Landscape of US Robotics in 2025

The US robotics market is experiencing an unprecedented surge, transforming industries from manufacturing to healthcare. This growth is not merely incremental but rather a rapid evolution fueled by significant investments in R&D, widespread adoption of AI, and a pressing need for automation to address labor challenges and enhance operational efficiency. The landscape for 2025 is marked by intense innovation and strategic deployment, positioning robotics as a critical component of economic growth and competitive advantage.

Drivers of Rapid Growth and Market Expansion

Several key factors are propelling the robotics market forward at an accelerated pace. These include the decreasing cost of robotic systems, advancements in artificial intelligence and machine learning that enable more sophisticated tasks, and the increasing demand for automation in sectors facing persistent labor shortages or requiring high precision and safety. The convergence of these elements creates a fertile ground for exponential growth across various applications.

One significant driver is the push for “Lights Out” manufacturing, where facilities can operate with minimal to no human intervention, primarily leveraging robotic systems. This not only optimizes production lines but also reduces operational costs and improves safety in hazardous environments. The integration of collaborative robots, or ‘cobots,’ further enhances this trend, allowing humans and robots to work side-by-side, augmenting human capabilities rather than replacing them entirely.

* Technological Advancements: Continuous breakthroughs in AI, computer vision, and gripper technology.

* Cost-Effectiveness: Declining capital expenditure for robotic systems and improved ROI.

* Labor Shortages: Addressing workforce gaps in critical sectors like manufacturing and logistics.

* Enhanced Efficiency and Safety: Robots performing repetitive, dangerous, or precise tasks.

The market’s expansion is also buoyed by supportive government policies and initiatives aimed at fostering technological innovation and domestic manufacturing. Grants for robotics research, tax incentives for automation adoption, and educational programs to build a skilled workforce are all contributing to a robust ecosystem for robotics development and deployment. This supportive environment encourages businesses to invest in robotic solutions, accelerating market penetration and scaling capabilities.

Furthermore, the recent global disruptions have underscored the importance of resilient supply chains and localized production. Robotics offers a viable solution to achieve both, by enabling onshoring of manufacturing processes and creating more agile distribution networks. This strategic imperative is pushing companies to adopt robotic solutions at a faster rate, ensuring business continuity and competitive advantage in a volatile global economy. The drive towards more sustainable practices is also influencing robotics adoption; advanced robots can optimize resource usage and reduce waste, aligning with environmental objectives.

Healthcare Robotics: A New Era of Precision and Care

The healthcare sector is witnessing transformative growth in robotics, moving beyond surgical assistance to encompass a wide array of applications that redefine patient care and operational efficiency. In 2025, this segment is projected to be one of the fastest-growing due to an aging population, rising demand for advanced medical procedures, and the need to alleviate the burden on human staff. From automated pharmacies to disinfection robots, healthcare robotics is revolutionizing the industry.

Surgical Robotics and Minimally Invasive Procedures

Surgical robotics, exemplified by systems like the da Vinci Surgical System, have already established a strong foothold. These robots provide surgeons with enhanced dexterity, precision, and visualization, leading to superior patient outcomes, reduced recovery times, and fewer complications. The next few years will see further refinement of these systems, incorporating haptic feedback, AI-driven guidance, and even greater autonomy for specific tasks, supervised by medical professionals.

Beyond traditional surgery, interventional robotics is also gaining traction, particularly in cardiology and neurology. These robots can navigate complex anatomical structures with unparalleled precision, facilitating procedures that were once deemed too risky or difficult. The advancements in imaging technologies combined with robotic control allow for real-time adjustments and personalized treatments, pushing the boundaries of what is possible in less invasive medicine.

* Enhanced Precision: Minimizing human error in delicate procedures.

* Reduced Recovery Times: Smaller incisions lead to quicker patient healing.

* Improved Patient Outcomes: Lower complication rates and better long-term health.

The adoption of surgical robots is also being driven by the economic benefits. While initial investment can be substantial, the long-term savings from shorter hospital stays, fewer readmissions, and reduced staffing needs make a compelling case for their integration. Furthermore, the ability of these systems to integrate with telemedicine platforms allows for remote assistance and training, expanding access to specialized care in underserved areas. This blend of clinical and economic advantages positions surgical robotics at the forefront of healthcare innovation.

Robot-assisted rehabilitation is another burgeoning area. Exoskeletons and motorized braces are helping patients regain mobility and function after injuries or strokes, often with more intensive and consistent therapy than human therapists can provide alone. These devices offer quantifiable data on patient progress, enabling clinicians to tailor rehabilitation plans with greater precision and effectiveness. The integration of virtual reality with robotic rehabilitation also adds an engaging and immersive dimension to therapy sessions.

Pharmacy Automation and Logistics Robotics

Within healthcare facilities, automation extends to pharmacy operations and logistics. Robotic systems are now capable of dispensing medications, compounding sterile preparations, and managing inventory with unparalleled accuracy and efficiency. This not only reduces dispensing errors, a critical safety concern, but also frees up pharmacists and technicians to focus on direct patient care and clinical interventions.

Logistics robots, including automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), are transforming hospital operations. They transport linens, meals, medical supplies, and even waste between departments, ensuring timely delivery and reducing the physical strain on staff. These systems operate around the clock, improving the flow of materials and increasing overall institutional efficiency, particularly in large and complex hospital environments.

Logistics and Warehousing: The Backbone of E-commerce

The explosion of e-commerce has put immense pressure on logistics and warehousing operations, demanding unprecedented speed, accuracy, and efficiency. Robotics is emerging as the critical solution, driving transformative change in how goods are stored, picked, packed, and shipped. This sector is experiencing phenomenal growth, propelled by the need to meet ever-increasing consumer expectations for rapid delivery and cost-effective operations.

Autonomous Mobile Robots (AMRs) and Automated Storage and Retrieval Systems (AS/RS)

Autonomous Mobile Robots (AMRs) are revolutionizing warehouse layouts and workflows. Unlike traditional Automated Guided Vehicles (AGVs) that follow fixed paths, AMRs navigate dynamically using onboard sensors and sophisticated mapping software. They transport goods, assist in order fulfillment, and even handle inventory counts, optimizing space utilization and improving overall throughput. Their flexibility allows for rapid deployment and easy reconfiguration of warehouse operations to adapt to changing demands.

Automated Storage and Retrieval Systems (AS/RS) are another cornerstone of modern warehousing. These robotic systems automatically place and retrieve items from high-density storage locations, maximizing vertical space and minimizing human travel time. AS/RS solutions range from crane-based systems handling pallets to shuttle systems for smaller cartons, all designed to enhance storage capacity and accelerate order fulfillment processes. The synergy between AMRs and AS/RS creates highly efficient, lights-out warehouse environments.

* Increased Throughput: Faster processing of orders and higher volume capacity.

* Reduced Labor Costs: Automation lessens reliance on manual labor for repetitive tasks.

* Improved Accuracy: Minimizing picking errors and inventory discrepancies.

The integration of artificial intelligence with these systems is also paramount. AI algorithms optimize picking routes, balance workloads between robots, and predict demand patterns, allowing for proactive inventory management. This predictive capability is crucial in a market characterized by fluctuating demand and the need for just-in-time inventory strategies. The data gathered by these robotic systems also provides invaluable insights for continuous process improvement and strategic planning.

Furthermore, the challenges posed by labor availability and rising wages in the logistics sector make robotics an increasingly attractive investment. Robots can work tirelessly, perform repetitive tasks without fatigue, and operate in environments unsuitable for humans. This capability enhances worker safety by removing them from potentially hazardous areas and allows human employees to focus on more complex, value-added tasks such as quality control, exception handling, and strategic oversight. The scalability of robotic deployments also means companies can rapidly expand their capacity during peak seasons without the overhead of hiring and training a seasonal workforce.

Agricultural Robotics: Cultivating the Future of Farming

Agricultural robotics is rapidly becoming indispensable, addressing critical challenges faced by the farming industry: labor shortages, environmental sustainability, and the demand for increased yields. As of 2025, this sector is experiencing exponential growth, driven by innovations in automation, AI, and sensor technology that are transforming traditional farming practices into precision agriculture. From planting to harvesting, robots are cultivating a more efficient and sustainable future.

Precision Agriculture and Autonomous Vehicles

Precision agriculture relies heavily on robotic systems and autonomous vehicles to optimize resource use and maximize crop yields. Field robots equipped with sophisticated sensors can monitor soil conditions, plant health, and pest infestations at a granular level, providing farmers with data-driven insights for targeted interventions. This approach minimizes the use of water, fertilizers, and pesticides, leading to more sustainable farming practices and reduced environmental impact.

Autonomous tractors and drones are revolutionizing fieldwork. Drones collect aerial imagery for crop analysis, while autonomous tractors can perform tasks like plowing, planting, and spraying with unparalleled accuracy and consistency, often operating 24/7 without human fatigue. These vehicles integrated with GPS and AI, ensure precise execution of tasks, optimizing seed placement, nutrient delivery, and weed control, all contributing to healthier crops and higher yields.

* Resource Optimization: Precise application of water, fertilizers, and pesticides.

* Increased Efficiency: Autonomous operation minimizes human labor and downtime.

* Improved Yields: Data-driven decision-making leads to healthier crops.

The financial implications are also significant. While the initial investment in agricultural robotics can be high, the long-term savings in labor costs, reduced input expenditures, and increased crop value provide a strong return on investment. Furthermore, the ability of these robots to collect and analyze vast amounts of data helps farmers make more informed decisions, leading to better crop management strategies and enhanced profitability. This shift towards data-intensive farming is a core component of the agricultural revolution.

Automated Harvesting and Livestock Management

Beyond field operations, robotics is transforming harvesting and livestock management. Robotic harvesters are being developed for delicate crops like strawberries and tomatoes, which are typically labor-intensive to pick. These robots use computer vision and dexterous grippers to identify ripe produce and harvest it gently, reducing damage and increasing efficiency. This innovation addresses the significant seasonal labor challenges faced by specialty crop growers.

In livestock farming, robots are performing tasks such as automated milking, precise feeding, and disease monitoring. Robotic milking systems allow cows to be milked on demand, improving animal welfare and milk production efficiency. Automated feeding systems dispense exact rations, minimizing waste and optimizing animal health. Furthermore, autonomous systems can monitor animal behavior and vital signs, alerting farmers to potential health issues early, leading to better animal care and reduced losses.

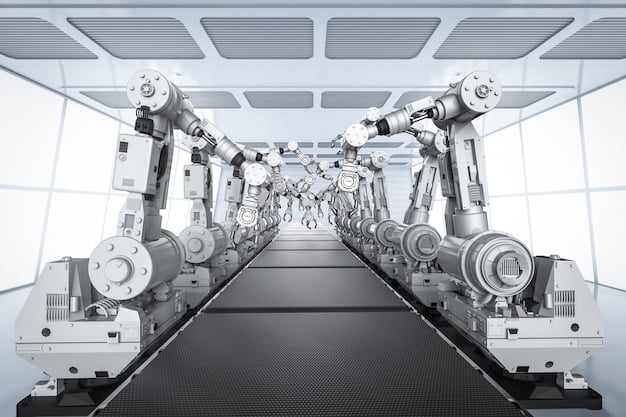

Manufacturing and Industrial Robotics: The Evolving Factory Floor

Manufacturing has long been the stronghold of industrial robotics, serving as the earliest adopters of automation for repetitive and high-volume tasks. In 2025, this sector continues its robust growth, characterized by the integration of more sophisticated, flexible, and collaborative robotic systems. The focus has shifted from mere automation to smart manufacturing, where robots are integral to interconnected, data-driven production environments.

Collaborative Robots (Cobots) and Advanced Grippers

Collaborative robots, or ‘cobots,’ are defining the next generation of industrial automation. Designed to work safely alongside human operators without the need for extensive safety caging, cobots are incredibly versatile. They can assist with assembly tasks, material handling, quality inspection, and even delicate finishing processes. Their ease of programming and flexibility make them ideal for small and medium-sized enterprises (SMEs) that previously found traditional industrial robots too complex or costly.

Advancements in gripper technology are also a significant driver of growth. Modern grippers are more adaptable, capable of handling a wider variety of materials and shapes, from delicate electronics components to irregularly shaped food items. This includes soft grippers for fragile objects, force-sensing grippers for precision assembly, and multi-functional grippers that can adapt to different tasks, significantly expanding the scope of robotic applications in manufacturing.

* Increased Dexterity: Handling complex assembly and varied materials.

* Human-Robot Collaboration: Enhancing productivity through safe interaction.

* Flexibility: Easily re-deployable for different tasks and production lines.

The evolution of cobots extends beyond mere safety; they are increasingly integrated with AI to learn from human demonstration and adapt to changing production requirements. This learning capability allows for faster setup times and greater adaptability to product variations, which is vital in markets demanding high customization and short product lifecycles. Their ability to work directly with humans also facilitates knowledge transfer, ensuring that human expertise is leveraged to train and supervise robotic workflows, thereby optimizing performance.

Furthermore, the rise of Industry 5.0 concepts emphasizes the human-centric approach, where technology like cobots is used to augment human capabilities rather than replace them. This paradigm focuses on creating more engaging and safer work environments, where robots handle the strenuous or monotonous tasks, freeing up human workers to focus on creative problem-solving, quality assurance, and customer interaction. The seamless integration of these robots into existing workflows minimizes disruption and maximizes overall output.

Automated Quality Control and Inspection

Robots are playing an increasingly critical role in quality control and inspection processes. Equipped with high-resolution cameras, laser scanners, and other sensory technologies, robots can perform rapid and highly accurate inspections of manufactured parts, identifying defects that might be missed by the human eye. This ensures consistent product quality, reduces waste, and helps maintain brand reputation.

The data collected by these inspection robots can be fed back into the manufacturing process in real-time, enabling immediate adjustments and proactive problem-solving. This closed-loop system, often part of a broader “smart factory” initiative, minimizes the production of faulty goods and optimizes resource utilization. From automotive components to consumer electronics, robotic inspection is becoming a standard practice for maintaining rigorous quality standards.

Service Robotics: Expanding Beyond the Industrial Floor

Service robotics, encompassing everything from commercial cleaning drones to restaurant automation, represents a rapidly diversifying and expanding segment of the US robotics market. As we move into 2025, this sector’s growth is fueled by increasing demand for automation in consumer-facing industries, driven by labor challenges, hygiene concerns, and the pursuit of enhanced customer experiences. These robots are quietly, yet profoundly, reshaping daily life and commercial operations.

Hospitality and Food Service Automation

The hospitality and food service industries are experiencing a significant uptake in robotic solutions. From automated baristas preparing custom beverages to robotic chefs assisting with food preparation in commercial kitchens, these systems address labor shortages and ensure consistency in product quality. Delivery robots are also becoming more common in hotels and restaurants, ferrying meals and amenities to guests, thereby improving service efficiency and reducing wait times.

Cleaning and disinfection robots are also gaining prominence, particularly in post-pandemic environments. Autonomous scrubbers and UV-C light disinfection robots are deployed in hotels, airports, and public spaces to maintain high standards of hygiene and safety. These robots operate with greater consistency and thoroughness than manual cleaning, often working overnight or during off-peak hours, ensuring a clean and safe environment for patrons and staff alike.

* Increased Efficiency: Faster service delivery and consistent quality.

* Enhanced Hygiene: Automated cleaning reduces germ transmission.

* Addressing Labor Shortages: Filling roles that are difficult to staff.

The customization and personalization capabilities of service robots are also a key differentiator. For example, robots in retail can guide customers to specific products, provide detailed information, and even assist with checkout processes, enhancing the shopping experience. In public spaces, interactive robots can offer directions, answer frequently asked questions, and provide entertainment, transforming passive environments into engaging experiences. This focus on customer interaction and personalized service opens up new avenues for growth and value creation.

Retail and Customer Engagement Robotics

In the retail sector, robots are optimizing inventory management, assisting customers, and even providing unique shopping experiences. Inventory robots autonomously patrol aisles, scanning shelves to identify misplaced items, stockouts, and pricing errors, providing real-time data to store managers. This automation significantly reduces the time spent on manual inventory checks and improves stock accuracy.

Customer service robots, ranging from humanoid assistants to interactive kiosks, are being deployed in stores to greet customers, answer queries, and guide them to products. These robots can provide information in multiple languages, making shopping more accessible and enjoyable for a diverse customer base. Some advanced retail robots even offer personalized recommendations based on customer preferences and past purchases, blurring the lines between online and in-store shopping experiences.

Challenges and Opportunities in the US Robotics Market 2025

While the growth trajectory for the US robotics market in 2025 is overwhelmingly positive, navigating this dynamic landscape involves inherent challenges as well as abundant opportunities. Addressing these aspects strategically will be crucial for sustained growth and the successful integration of robotics across diverse sectors. From ethical considerations to workforce retraining, the path forward requires careful planning and adaptive solutions.

Ethical Considerations and Public Perception

The rapid advancement of robotics invariably brings ethical considerations to the forefront. Issues such as data privacy, algorithmic bias, and the potential impact on employment require careful deliberation and the development of robust regulatory frameworks. Ensuring that robots are developed and deployed responsibly, with human well-being at the core, is paramount to fostering public acceptance and trust.

Public perception plays a significant role in widespread adoption. Concerns about job displacement often overshadow the benefits of automation, such as job creation in new areas, dangerous task elimination, and increased productivity. Transparent communication about the complementary nature of human-robot collaboration and the economic advantages for society as a whole will be crucial in shaping a positive narrative and overcoming resistance to change.

* Job Displacement Fears: Addressing concerns through retraining and new role creation.

* Data Privacy: Establishing robust protection for information collected by robots.

* Algorithmic Bias: Ensuring AI systems are fair and equitable.

The development of ethical AI guidelines and responsible robotics design principles is actively underway in various research institutions and industry consortiums. This collaborative effort aims to proactively address potential negative societal impacts and build public confidence in robot technologies. Emphasizing the enhancement of human capabilities and quality of life through robotics, rather than just automation, is key to shifting perception.

Workforce Adaptation and Skill Development

The integration of robotics necessitates a significant shift in the workforce. While robots may automate certain repetitive tasks, they also create new roles in programming, maintenance, data analysis, and human-robot interaction. The opportunity lies in proactively investing in education and training programs to upskill and reskill the existing workforce, preparing them for the jobs of tomorrow. This includes vocational training, online courses, and apprenticeships.

Companies that successfully integrate robotics will be those that invest not only in the technology but also in their people. This involves fostering a culture of continuous learning and adaptation. Government initiatives and public-private partnerships will also be vital in bridging the skills gap and ensuring a smooth transition for workers affected by automation. This focus on human capital development transforms potential challenges into opportunities for economic growth and societal advancement.

Conclusion

Conclusion

The US Robotics Market Analysis: Which Sectors are Seeing the Fastest Growth in 2025? unequivocally points towards a future where automation is not just a trend, but a fundamental pillar of economic and societal progress. Healthcare, logistics, and agricultural robotics are currently leading the charge, driven by innovation, necessity, and strategic investment. While challenges remain, particularly around ethical considerations and workforce adaptation, the transformative potential of robotics far outweighs these hurdles. The journey towards a more automated, efficient, and interconnected America is well underway, with robots playing an increasingly central role in shaping the industries of tomorrow.

| Key Sector | Growth Catalyst & Impact |

|---|---|

| 🏥 Healthcare Robotics | Driven by aging populations & demand for precision. Enhances patient care and operational efficiency. |

| 📦 Logistics & Warehousing | Fueled by e-commerce boom and labor shortages. Increases speed, accuracy, and throughput in fulfillment. |

| 🌾 Agricultural Robotics | Addresses labor scarcity and sustainability goals. Optimizes resource use, enhances yields, and precision. |

| 🏭 Manufacturing & Industry | Evolving with cobots & smart factories. Boosts efficiency, quality control, and human-robot collaboration. |

Frequently Asked Questions

▼

The rapid growth is driven by several factors, including advancements in AI and machine learning, decreasing costs of robotic systems, persistent labor shortages across various industries, and a growing demand for enhanced efficiency and safety in operations. These elements collectively create a compelling environment for widespread robotics adoption.

▼

Key challenges include initial investment costs, the need for skilled labor to operate and maintain robots, concerns about job displacement, and the development of robust ethical frameworks. Overcoming these requires significant investment in education, training, and careful policy development to ensure a smooth transition.

▼

Robotics are transforming healthcare through surgical assistance for precision procedures, automating pharmacy operations for accuracy, and deploying logistics robots for efficient material transport. They are also vital in patient rehabilitation, enhancing care quality and improving operational efficiency across medical facilities.

▼

Autonomous tractors and drones for precision agriculture are highly impactful, optimizing planting, spraying, and monitoring crop health. Robotic harvesters for delicate produce and automated systems for livestock management are also significantly boosting efficiency, addressing labor shortages, and promoting sustainable farming practices.

▼

Cobots are crucial because they can work safely alongside humans, increasing flexibility and efficiency in assembly, handling, and inspection tasks without extensive safety guarding. Their ease of programming and adaptability make them ideal for various industries, fostering human-robot collaboration and enhancing productivity in modern factory floors.