US Robotics Safety Standards and Warehouse Automation Impact

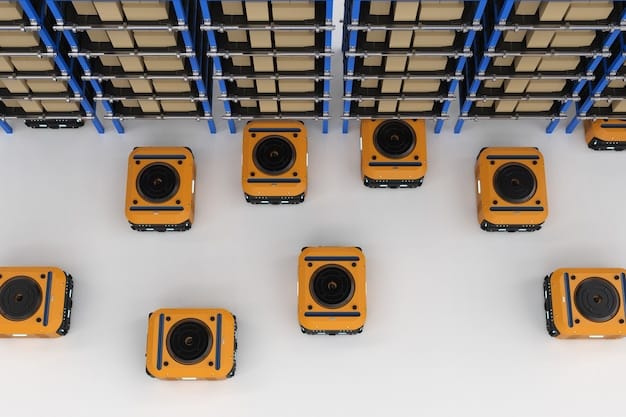

The new US robotics safety standards will significantly impact warehouse automation projects by demanding enhanced safety protocols, fostering innovation in collaborative robotics, and necessitating revised operational strategies to ensure compliance and worker well-being.

As warehouse automation projects increasingly integrate advanced robotics, a pivotal question arises: How Will the New US Robotics Safety Standards Affect Warehouse Automation Projects? These evolving regulations are more than mere bureaucratic hurdles; they represent a fundamental shift towards enhancing safety, fostering innovative robotics development, and ensuring the seamless collaboration between human workers and intelligent machines within dynamic warehouse environments.

Understanding the Landscape of Robotics Safety Standards

The acceleration of automation in warehouse operations has underscored the critical need for robust safety frameworks. The interplay between sophisticated machinery and human workers necessitates a comprehensive approach to risk mitigation. New US robotics safety standards are not being developed in a vacuum; they reflect a global move towards harmonized safety protocols.

These standards, often derived from organizations like the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI), are designed with a primary objective: preventing incidents, injuries, and fatalities in environments where humans and robots share space. This proactive stance aims to create a safer work environment, boost worker confidence, and ultimately drive the more effective adoption of automation technologies.

Key Regulatory Bodies and Their Influence

Several key bodies contribute to the development and enforcement of robotics safety standards in the US. Their individual mandates and collaborative efforts form a complex, yet essential, regulatory ecosystem. Understanding their roles is crucial for any warehouse looking to implement or expand automation.

- OSHA (Occupational Safety and Health Administration): As the primary federal agency responsible for worker safety, OSHA sets and enforces standards for safe and healthful working conditions. While not creating specific robotics standards, OSHA relies on consensus standards (like ANSI/RIA R15.06) to enforce workplace safety related to robotics.

- ANSI (American National Standards Institute): ANSI facilitates the development of voluntary consensus standards by accredited organizations. It is not a government agency, but its standards are widely adopted and often referenced by OSHA and other regulatory bodies, making them de facto requirements.

- RIA (Robotics Industries Association): Now part of A3 (Association for Advancing Automation), the RIA is a significant voice in robotics safety. It develops and publishes comprehensive safety standards, such as the widely referenced ANSI/RIA R15.06, which provides guidelines for the safe integration, installation, and use of industrial robots.

The collective emphasis from these bodies on risk assessment, safety-rated control systems, and human-robot interaction is reshaping how warehouse automation projects are conceived and executed. Compliance is no longer just about avoiding penalties; it’s about embedding safety into the very fabric of operational design.

In essence, the ongoing evolution of these standards reflects a proactive commitment to ensuring that the benefits of warehouse automation are realized without compromising the well-being of the workforce. They serve as a foundational layer, ensuring that innovation proceeds responsibly and ethically.

Impact on Warehouse Design and Layout

The introduction of new robotics safety standards in the US has a profound effect on the fundamental design and layout of automated warehouses. No longer can robotics be integrated as an afterthought; safety must be embedded from the initial stages of conceptualization and planning. This necessitates a holistic rethinking of the physical space and the operational flows within it.

Designing for safety means considering not just the robots themselves, but also the paths they take, their interaction zones, and emergency protocols. This proactive approach can prevent costly retrofits and ensure continuous operational efficiency.

Redefining Human-Robot Collaborative Zones

One of the most significant shifts driven by new safety standards is the redefinition of collaborative zones. Warehouses are increasingly moving towards environments where humans and robots work side-by-side, rather than being strictly separated. This requires sophisticated safety mechanisms.

New standards emphasize dynamic safety systems, such as advanced sensor arrays that can detect human presence and proximity, allowing robots to adjust their speed or halt entirely. This fosters a safer, more integrated workflow. It also means that existing layouts might need modifications to accommodate larger safety perimeters or specialized traffic lanes.

The design must account for:

- Clear Path Markings: Designated pathways for both robots and humans, clearly marked and well-maintained, are becoming standard. This minimizes cross-traffic and potential collision points.

- Safety Guarding and Barriers: While collaborative robots reduce the need for rigid guarding, traditional industrial robots still require physical barriers or light curtains to prevent human entry into hazardous zones during operation. Standards are refining the requirements for these safeguards.

- Emergency Stop Accessibility: Ensuring that emergency stop buttons are highly visible and easily accessible to all personnel is critical. This includes both fixed emergency stops and portable options for mobile robotics.

The evolution of safety standards is pushing for more intelligent warehouse designs that optimize both human safety and robotic efficiency. This requires a strong understanding of both engineering principles and human factors.

The Crucial Role of Risk Assessment and Mitigation

In the context of new US robotics safety standards, risk assessment is no longer a peripheral task but a foundational pillar of any warehouse automation project. It’s a continuous, iterative process that must begin long before any robot is deployed and continue throughout its operational lifespan. The standards mandate a systematic identification of potential hazards and the implementation of robust mitigation strategies.

This comprehensive approach ensures that all foreseeable risks, from physical impact to unexpected robotic behavior, are addressed proactively. It moves beyond generic safety checklists to a tailored, deep dive into specific operational scenarios.

Implementing Comprehensive Safety Systems

Mitigating identified risks requires the integration of sophisticated safety systems. These systems are designed to monitor robotic operations, detect anomalies, and initiate corrective actions, often without human intervention. The new standards strongly advocate for multilayered safety measures.

This includes both hardware-based and software-based solutions. Advanced sensor technologies, for instance, play a crucial role in preventing collisions and ensuring safe distances. Predictive maintenance informed by data analytics also contributes to risk reduction by preventing unexpected equipment failures.

Key components of such systems include:

- Safety-Rated Sensor Technology: Lidar, radar, machine vision, and safety mats are integral for detecting human presence and maintaining safe operating distances around robots. These sensors must meet specific performance levels as defined by safety standards.

- Fail-Safe Design Principles: Robotic systems are increasingly designed to default to a safe state in the event of a power failure, component malfunction, or communication loss. This includes mechanisms that prevent unexpected restarts.

- Advanced Emergency Protocols: Beyond standard emergency stops, there’s a growing emphasis on intelligent emergency procedures that can bring robots to a safe, controlled stop, minimizing risks to personnel and equipment during unforeseen events.

The ability to accurately assess and effectively mitigate risks is paramount. It demonstrates a commitment to worker safety and operational resilience, ensuring that automation projects are both innovative and secure.

Technological Innovations Driven by Safety Demands

The stringent requirements of new US robotics safety standards are proving to be a powerful catalyst for technological innovation within the warehouse automation sector. Rather than merely compliance burdens, these standards are stimulating the development of more intelligent, adaptable, and inherently safer robotic systems. Manufacturers and integrators are now compelled to push the boundaries of what’s possible in robotics design.

This drive for safety-centric innovation is leading to breakthroughs in areas such as human-robot interaction, predictive maintenance, and autonomous navigation, ultimately resulting in more sophisticated and reliable automation solutions.

Advancements in Collaborative Robotics (Cobots)

Perhaps the most prominent area of innovation directly influenced by safety standards is the evolution of collaborative robots, or “cobots.” Designed to work alongside humans without traditional safety cages, cobots exemplify the shift towards integrated workspaces. New safety standards are pushing cobot development even further.

This includes enhancing their ability to sense and respond to their environment in real-time, making them more intuitive and safer partners. The focus is on increasing their intelligence to anticipate human movements and react preemptively, rather than merely reacting to contact.

Innovations in cobots include:

- Enhanced Force and Power Limiting: New generations of cobots are equipped with more precise internal sensors that can limit the force and power of their movements, ensuring that any accidental contact with a human remains below injury thresholds.

- Advanced Vision Systems: Sophisticated vision systems allow cobots to “see” their surroundings with greater clarity, identifying humans, obstacles, and the precise location of objects, enabling safer navigation and task execution.

- Intuitive Programming Interfaces: Simplifying how cobots are programmed and taught tasks reduces the likelihood of human error during setup, contributing to overall safety. Lead-through programming and graphical interfaces are becoming standard.

These technological leaps are not only making warehouses safer but also unlocking new possibilities for flexible and efficient automation, blurring the lines between human and machine capabilities.

Training and Workforce Adaptation Requirements

The advent of new US robotics safety standards necessitates a significant evolution in workforce training and adaptation within warehouse automation projects. It’s no longer sufficient for employees to simply operate machinery; they must possess a profound understanding of robotic safety protocols, human-robot interaction dynamics, and emergency procedures. This shift demands comprehensive training programs that go beyond basic operational instructions.

A well-trained workforce is the first line of defense against incidents, enhancing not only safety but also operational efficiency and confidence in automated systems.

Developing a Safety-First Culture

Beyond formal training, the new standards compel warehouses to cultivate a pervasive safety-first culture. This means embedding safety consciousness into every aspect of daily operations and fostering a proactive mindset among all employees, from the factory floor to management. It’s about empowering workers to identify and report potential hazards and to actively participate in safety discussions.

This cultural shift is critical for the effective implementation and sustained success of automated systems. It transforms safety from a compliance burden into a shared responsibility and a core value.

Key elements of this cultural development include:

- Continuous Education and Recertification: Safety training shouldn’t be a one-off event. Regular refreshers, updates on new protocols, and recertification programs ensure that knowledge remains current and deeply ingrained.

- Scenario-Based Training: Moving beyond theoretical knowledge, training should involve practical, hands-on simulations of hazardous scenarios, allowing employees to practice emergency responses in a controlled environment.

- Promoting Open Communication: Creating channels for employees to voice safety concerns, report near misses, and suggest improvements without fear of reprisal is essential for continuous safety enhancement.

Ultimately, a workforce that is not only skilled in operating automated systems but also deeply committed to safety protocols is invaluable. It ensures that the sophisticated technology being deployed is managed with the utmost care and responsibility.

Economic Implications for Warehouse Operations

The integration of new US robotics safety standards carries significant economic implications for warehouse automation projects. While the immediate focus might be on the costs associated with compliance, a broader perspective reveals both challenges and opportunities. These standards influence everything from initial capital expenditure to long-term operational efficiencies and competitive positioning.

Understanding these economic ripples is crucial for strategic planning and for realizing the full return on investment from automation.

Balancing Compliance Costs with Long-Term Benefits

Initially, warehouse operators may perceive compliance as an added expense, factoring in the cost of new safety-certified equipment, system upgrades, extensive training programs, and the time invested in risk assessments. However, these upfront investments are often offset by substantial long-term benefits that contribute to overall profitability and sustainability.

The cost of non-compliance, including potential fines, reputational damage, increased insurance premiums, and the debilitating impact of accidents on productivity, far outweighs the cost of proactive safety measures. Investing in safety is, in essence, investing in operational resilience.

Long-term benefits include:

- Reduced Downtime and Increased Productivity: A safer environment means fewer accidents, leading to less production downtime, higher morale, and uninterrupted workflow. This directly translates to increased output and efficiency.

- Lower Insurance Premiums: Companies with strong safety records and demonstrated compliance with industry standards often qualify for lower insurance rates, providing a direct cost saving.

- Enhanced Workforce Retention and Morale: A commitment to worker safety fosters a positive work environment, leading to higher employee satisfaction, reduced turnover, and a more engaged and productive workforce.

- Competitive Advantage: Warehouses with superior safety standards can differentiate themselves in the market, attracting top talent and potentially drawing in clients who prioritize ethical and safe operational practices.

Ultimately, while there are direct costs associated with meeting new safety standards, these are strategic investments. They enhance operational stability, reduce long-term risks, and contribute to a stronger, more sustainable business model.

Looking Ahead: The Future of Warehouse Automation Safety

The new US robotics safety standards are not static; they represent a dynamic and evolving framework that will continue to shape the future of warehouse automation. As technology advances and operational paradigms shift, these standards will adapt, becoming more sophisticated, proactive, and globally harmonized. The trajectory is towards increasingly intelligent safety systems that can learn and predict, further minimizing risks.

This continuous evolution promises even safer, more efficient, and more integrated human-robot work environments, ultimately transforming the very nature of logistics and supply chain management.

Anticipated Developments and Global Harmonization

The future of robotics safety in warehouses will likely see a greater emphasis on predictive safety, where AI and machine learning are employed to anticipate potential hazards before they occur. This moves beyond reactive safety measures to proactive prevention. Furthermore, there’s a strong drive towards global harmonization of safety standards, which would simplify compliance for multinational companies and foster greater international collaboration in robotics development.

The ongoing dialogue between industry leaders, regulatory bodies, and academic institutions will be critical in shaping these future standards. The goal remains constant: to ensure that the transformative power of automation is harnessed responsibly, safely, and sustainably.

| Key Aspect | Brief Description |

|---|---|

| ⚙️ Design & Layout | New standards demand proactive safety integration in warehouse design, redefining human-robot collaborative zones for enhanced safety and efficiency. |

| ⚠️ Risk Assessment | Mandates comprehensive, continuous risk assessment with implementation of sophisticated, multi-layered safety systems and fail-safe designs. |

| 💡 Tech Innovation | Drives advancements in collaborative robotics (cobots) with enhanced sensing, force limiting, and intuitive programming for safer human-robot interaction. |

| 🧑🤝🧑 Workforce Adaptation | Requires comprehensive training and the cultivation of a safety-first culture for operational efficiency and accident prevention. |

Frequently Asked Questions

▼

The primary organizations are OSHA (Occupational Safety and Health Administration), which enforces workplace safety through general and consensus standards; ANSI (American National Standards Institute), which facilitates voluntary consensus standards; and the RIA (Robotics Industries Association, now part of A3), which develops specific robotics safety standards like ANSI/RIA R15.06, widely adopted by the industry.

▼

New standards mandate that safety is integrated from the initial design phase of warehouses. This includes redefining human-robot collaborative zones with dynamic safety systems, requiring clear path markings, appropriate safety guarding, and easily accessible emergency stops to prevent incidents and ensure smooth operations.

▼

Risk assessment is a critical and continuous process under new standards. It involves systematically identifying potential hazards in automated environments and implementing robust mitigation strategies. This leads to the integration of sophisticated safety systems, including safety-rated sensors, fail-safe design principles, and advanced emergency protocols, to ensure proactive safety.

▼

Cobots are significantly impacted, driving innovation in their design for safer human-robot interaction. This includes advancements in force and power limiting, more sophisticated vision systems for environmental awareness, and intuitive programming interfaces. These enhancements allow cobots to work more closely and safely with humans without traditional physical barriers.

▼

While there are initial costs for compliance (equipment, training), these are strategic investments with long-term economic benefits. These include reduced downtime from accidents, lower insurance premiums, increased workforce retention and morale, and a competitive advantage through a demonstrated commitment to safety. Proactive safety measures ultimately lead to greater profitability and sustainability.

Conclusion

The new US robotics safety standards represent a transformative moment for warehouse automation projects. Far from being mere mandates, they are catalysts for innovation, demanding a fundamental rethinking of design, risk management, and human-robot interaction. While upfront investments in compliant technologies and comprehensive training will be necessary, the long-term benefits are substantial: enhanced worker safety, increased operational efficiency, reduced economic risks, and a reinforced competitive edge. As industry continues to embrace these evolving regulations, the future of automated warehouses promises to be not only more productive but also inherently safer and more resilient, fostering a harmonious synergy between advanced robotics and human ingenuity.